AIR COMPRESSOR FOR BLOWING MACHINE

Blowing machine air compressorPurified air used for breathing

- Energy-saving: more than 30% compared with piston oil free compressor

- Environment protection: nonuse of lubricate oil to avoid the environment pollution

- Reliability: absolutely guarantee oil free

- 100% oil-free compressed air

- 100% purified compressed air

- 100% oil pollution risk-free compressed system

Made of food-grade stainless steel

- High efficiency and Energy saving

- For new machine, energy saving 15%-20% compared with piston air compressor. After the wear of piston ring and cylinder body, energy saving 30%-40% compared with piston air compressor. The saved electric charges for 2 years operation equals to the machine’s purchase cost.

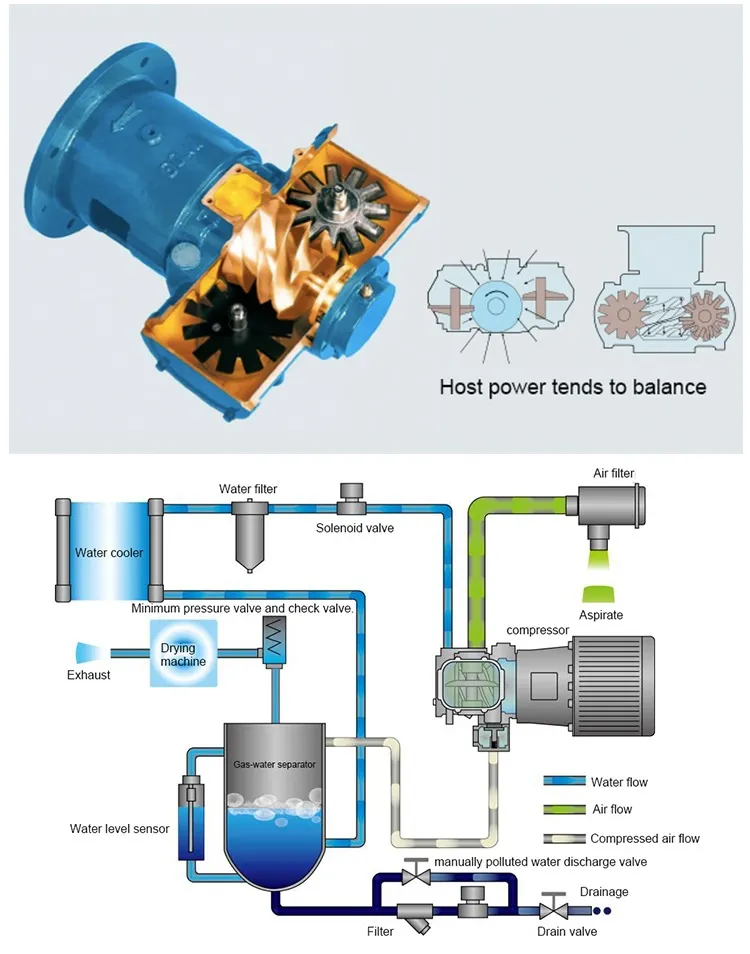

- box type design, no vibration, low noise, small

- Box type fully enclosed design, one revolution of the main shaft compresses 12 times, equal to 12-cylinder engine. No vibration of the air end, noise as low as 78dB, special design can reach 70dB, half area occupied and one third weight compared with conventional machine

- No wearing parts, maintenance period more than 5 years(50000hours).

- Fine structure, no wearing parts, the decrease of air production after 50000-hour working can be in 5%, maintenance period more than 5 years(50000 hours).

- Fewer consumable parts, less expenses Air filter element and water filter element only, less expenses. Environment, oil free design, 8573-1 oil free certification.

- Without any lubricate oil to avoid environment pollution and the compressed air is purified by the water in the stainless steel chamber.

- Isothermal compression, low exhaust temperature, low water ratio in compressed air.

- Compressing chamber temperature of the air end is no higher than 50 C. Working under normal temperature, the compressed air does not exceed 45C, low water ratio. All parts works under normal temperature, which prolongs the service life, enhances reliability and makes sure the low failure rate

- Simple management and maintenance

- EPG-CMN high-tech air compressor with high quality handles very easy, which can be connected with your DCS system by 485 interface. The working condition of the air compressor can be in control at all time

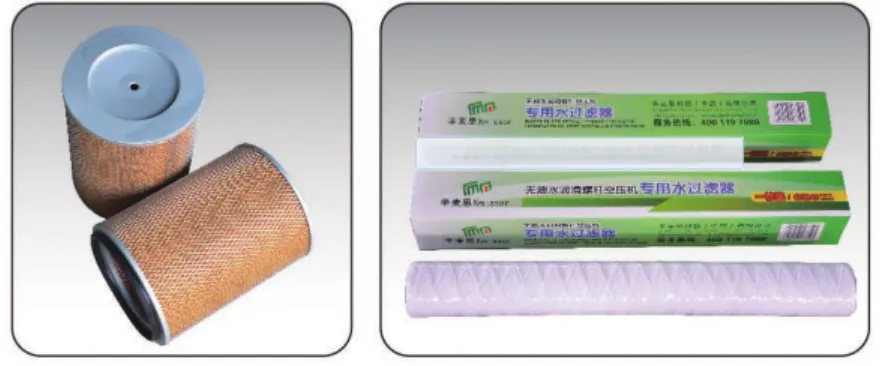

Consumable parts

Air filter element

The function of air filter element is to block the sucked impurities in air. Based on

environmental condition, replacement of the air filter element for each

500-2000 hours.

Water filter element

The function of water filter element is to block the impurities in the circulating water

and protect the air end. Based on environmental condition, replacement of the water

filter element for each 2000-4000 hours

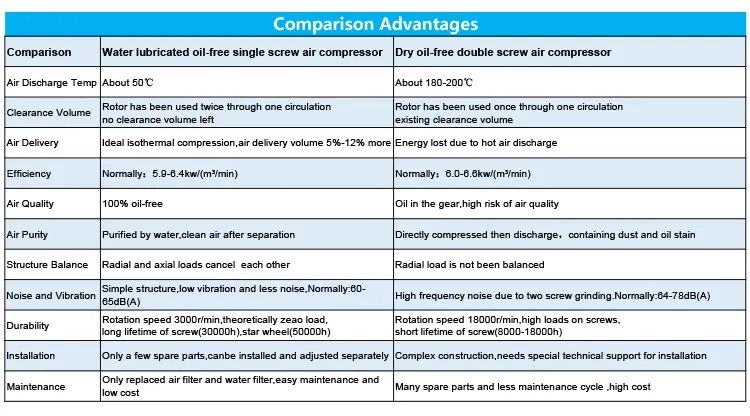

VibrationComparison of 40 bar medium pressure oil-free machine and 40 bar medium pressure oil-free piston air compressor

1.Structure comparison

| Item | 40 bar screw compressor | 40 bar piston compressor |

| Working principle |

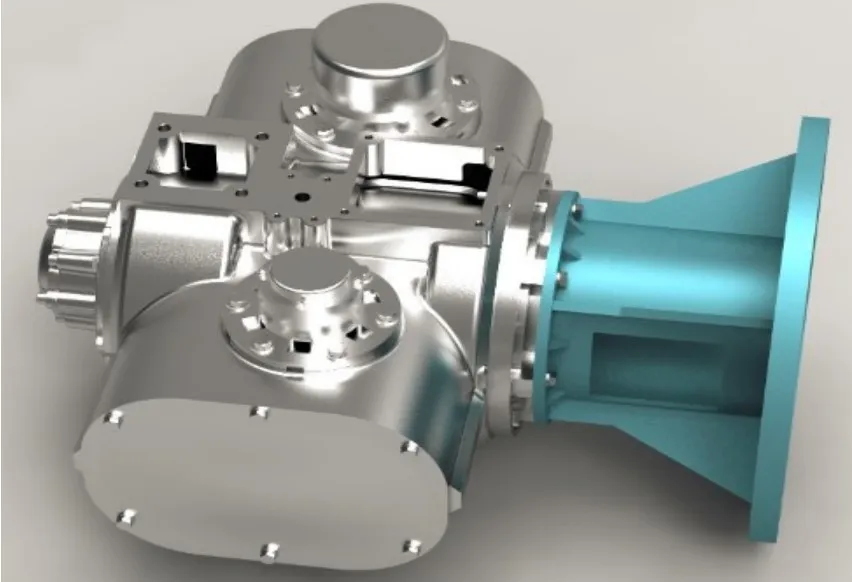

High precision star wheel screw, do rotational movement, change the volume of the cavity for compression, screw six spiral cavity, star wheel eleven teeth, arranged in parallel on both sides of the screw, forming two working compression cavity, screw rotation for a week is equivalent to compression 12 times, two-stage compression is equivalent to compression 24 times, equivalent to 24 cylinders of piston compressor in compression. Translated with www.DeepL.com/Translator (free version) |

The crankshaft drives the piston to do reciprocating motion and change the cylinder volume for compression. |

| Number of bearings | Three groups, diameter and axial force balance, shaft bearing force is small, long service life. | One group |

| Sealing system | Labyrinth seal plus mechanical seal | Packing |

| Number of compression stages | Two-stage screw compression | Three-stage piston compression or four-stage piston compression |

| Material | Compression machine and piping are made of stainless steel | Compression cylinder and other carbon steel, only the part of the pipeline with stainless steel |

| Compression main machine moving parts | Few moving parts: only the screw and star wheel are moving parts. | More moving parts: crankshaft, connecting rod, crosshead, stuffing box which need lubrication system, piston, piston ring, valve piece and so on above are moving parts. |

|

Efficiency |

Host structure is simple, compact, high precision, compression efficiency is above 95%, two-stage compression easily achieve 40 bar. host and motor direct connection. The world’s first dual motor drive design, in different pressure and gas consumption situation intelligent control system always maintain the most energy efficient transmission ratio, always maintain the most energy efficient operation. | Reciprocating piston type, complex structure, relying on the piston ring’s own elasticity, the ring outer circle and the head inside the fitting wall, due to wear and tear need to be replaced regularly, the transmission ratio is fixed, can not realize the transmission ratio change, high specific power, power consumption. |

| Vibration | The force is balanced, the power balance is good, the operation is smooth, the vibration is small, the vibration intensity is 4.5m/s. The coin standing on the main machine will not fall down when the unit is running. | There is an inertia force that cannot be eliminated and the vibration is large. |

| Noise | The noise is low, about one third of that of piston machine. | High noise level. |

| Motor | The motor is driven by permanent magnet motor which is equivalent to IE4 energy efficiency standard, and the motor efficiency reaches 97%. | Ordinary motor drive, the efficiency is about 94%, and the motor heat is large. |

| Driving method | Permanent magnet frequency conversion soft start, the starting current is very small. | Star-delta start, large starting current. |

| Gas supply mode | Constant pressure gas supply, gas supply range is automatically adjusted between 40% and 100%, power consumption is very economical. | Adding and unloading operation, the motor wastes 35% of electric energy when unloading. |

2.Comparison of compressed air quality

| Item | 40 bar screw compressor | 40 bar piston compressor |

| Particle impurities in compressed air | Because there is water lubrication, water plays a role in cleaning the air, with the air in the particles and other impurities stay in the water, out of the compressed air as fresh and clean as after the rain. | Dry compression, with the air in particles and moving parts particles, how much is discharged outward into the air-using system. |

| Oil content of compressed air | Compressed air oil content 0ppm, and through the third party German TUV class 0 oil-free certification | Compressed air contains oil, air particles and oil vapor volatilized by the packing will be mixed into the compressor cylinder, thus not achieve 100% oil-free, there is no oil-free piston machine companies through the German TUV class 0 oil-free certification |

| Compressed air water content | Compression host temperature host only about 45 ℃, about 45 ℃ water vapor mixture by the patented water vapor separation barrel for water, gas separation, (we all know that the lower the temperature, the less water content in the air) liquid water settled at the bottom of the water vapor barrel, clean air from the water vapor barrel, the water content is a quarter of the piston machine, piston machine does not go through the post-cooling temperature of 100 ℃ or more. | Because it is dry compression, the outlet temperature is above 100℃, and the water content is more than 4 times higher than the outlet temperature at 45℃. (We all know that the lower the temperature, the less gaseous moisture in the air) |

| Compressed air temperature | Without aftercooler 45℃ or so | More than 100℃ without aftercooler, also around 80℃ after aftercooler |

| Corrosive gases in the compressed air | Air particles, corrosive gases, etc. are cleaned by lubricating water and left in the water. The compressed air is cleaner, and the lubricating water is automatically replaced on a regular basis to ensure that the concentration is always in the low range, so there is also no corrosion of the corrosion-resistant material stainless steel. | Air particles, corrosive gases, etc., directly compressed, into the pipeline system, the piston compressor, carbon steel head, pipeline, hot delivery device, evaporator, etc. corrosion is obvious. |

Equipment management and safety comparison

| Item | 40 bar screw compressor | 40 bar piston compressor |

|

Operation safety |

When the machine is shut down, the compressor is pressure-free after the pressure release valve is released; when the machine is started again, it can be started directly. Since there is no pressure when the equipment is stopped, there is no accident of equipment failure or personal injury of personnel due to improper operation. | When the compressor is stopped: the pressure in the last compression chamber is still maintained at high pressure, and there is a risk of injury to personnel due to improper operation; when the compressor is started again, it needs to be relieved of pressure before it can be started, and there is a risk of equipment failure due to improper operation, and there is a risk of injury to people due to high pressure gas. |

| Oil-free safety | One hundred percent clean oil-free compressed air, one hundred percent to solve the risk of oil pollution | The crankcase has lubricating oil, relying on the stuffing box to block off the oil, and there is a risk of lubricating oil fleeing to the compression chamber if the stuffing box is worn out. |

| Fire safety | The operating temperature of compressor is low, only about 45℃, so there is no need to worry about high temperature spontaneous combustion of equipment and scalding accidents to personnel. | For dry compression, the temperature of the compression chamber can reach 200℃ or more, and there is a risk of high temperature spontaneous combustion and personnel burns. |

| Maintenance Cost | About 30,000 yuan per year for each unit | The annual maintenance cost of one unit is about 180,000 yuan. |

| Service life | The service life is more than three times that of a piston machine, and the compression main engine is designed to have a manufacturing life of 25 years without wearing parts. | 6000 hours or one year need head overhaul (or major maintenance) once |

Technical parameters

| Exhaust pressure | 2.0~3.2(adjustable pressure range) | Mpa |

| Discharge volume range | 9.6-24 | m3/min |

| Rated power | 90+110=220 | kW |

| Driving method | Direct link | (coupling connection) |

| Cooling method | Water cooling | |

| Exhaust temperature | ≤ ambient temperature +15 | ℃ |

| Noise | 55-72 | dB(A) |

| Dimension | 2250×2760×1670 | L×W×H(mm) |

| Compressed air outlet size | DN65 | |

| Total weight | 5200 | Kg |

| Rated working power | 3P 380V 50HZ | PH/V/HZ |

| Starting method | Permanent magnet inverter | |

| Motor protection grade | IP54 | Class F insulation |

Permanent magnet motor parameter table

|

|

Name |

Unit |

Value |

|

1 |

Rated power |

kW |

90+110 |

|

2 |

Rated Voltage |

V |

380 |

|

3 |

Rated current |

A |

/ |

|

4 |

Rated frequency |

Hz |

50 |

|

5 |

Rated speed |

rpm |

3000 |

|

6 |

Number of poles |

|

8 |

|

7 |

Protection grade |

IP |

54 |

|

8 |

Insulation grade |

|

F |

|

9 |

Cooling method |

|

Air-cooled |

|

10 |

Motor weight |

kg |

/ |

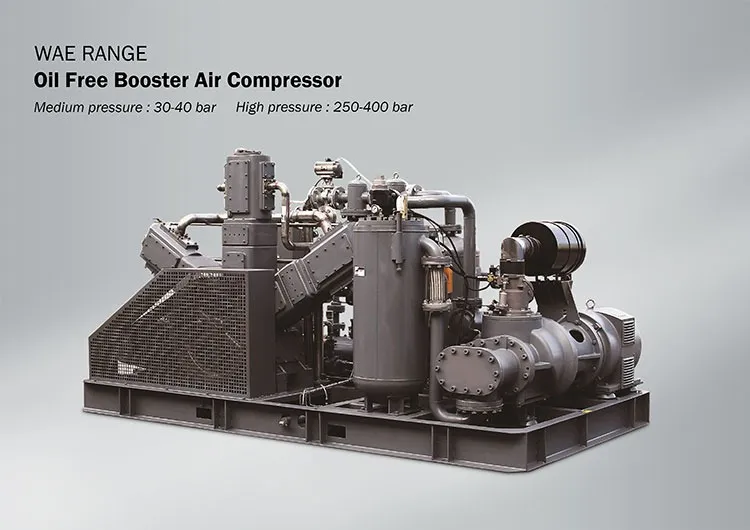

WAE range 25 bar high pressure air compressor is designed for the market of bottle blowing , food industry , medical industry , with the advantages:

1. Reliability

2. High efficiency and energy saving

3. Low noise

4. Pressure stability

5. Convenient transportation

6. 40 bar /250 bar/400 bar wide range option

7.Easy to move

8. convenient maintenance

9. Long operation life of spare parts , easy to purchase , low cost

10. Efficient and considerate service 25 bar high pressure air compressor

Techinical Specifications:

| Model no. |

Power kw |

FAW m3/min |

Pressure bar |

Speed rpm |

Air Outlet | Water inlet/outlet |

Weight kg |

Dimension mm |

| WAE-6.0/30-40 | 67 | 6.0 | 30-40 | 520 | DN40 | RC1-1/2″ | 3000 | 2760*1500*1500 |

| WAE-8.0/30-40 | 85 | 8.0 | 30-40 | 560 | DN40 | RC1-1/2″ | 3500 | 2760*1500*1500 |

| WAE-11.0/30-40 | 120 | 11.0 | 30-40 | 420 | DN40 | RC1-1/2″ | 4400 | 3620*1800*2000 |

| WAE-13.0/30-40 | 135 | 13 | 30-40 | 460 | DN40 | RC1-1/2″ | 4650 | 3620*2100*2000 |

| WAE-14.0/30-40 | 145 | 14.0 | 30-40 | 520 | DN40 | RC1-1/2″ | 4850 | 3620*2100*2000 |

| WAE-16.0/30-40 | 185 | 16.0 | 30-40 | 480 | DN50 | RC2″ | 5000 | 3620*2100*2000 |

| WAE-20.0/30-40 | 222 | 20.0 | 30-40 | 420 | DN50 | RC2″ | 7000 | 4165*2150*2100 |

| WAE-25.0/30-40 | 250 | 25.0 | 30-40 | 520 | DN65 | RC2-1/2″ | 8000 | 4590*2150*2100 |

| WAE-28.0/30-40 | 290 | 28.0 | 30-40 | 450 | DN65 | RC2-1/2″ | 8500 | 4590*2150*2100 |

| WAE-30.0/30-40 | 310 | 30.0 | 30-40 | 500 | DN65 | RC2-1/2″ | 10000 | 4590*2150*2100 |

| WAE-36.0/30-40 | 360 | 36.0 | 30-40 | 600 | DN65 | DN100 | 12000 | 6000*2300*2100 |

| WAE-40.0/30-40 | 410 | 40.0 | 30-40 | 680 | DN65 | DN100 | 13000 | 6500*2500*2300 |

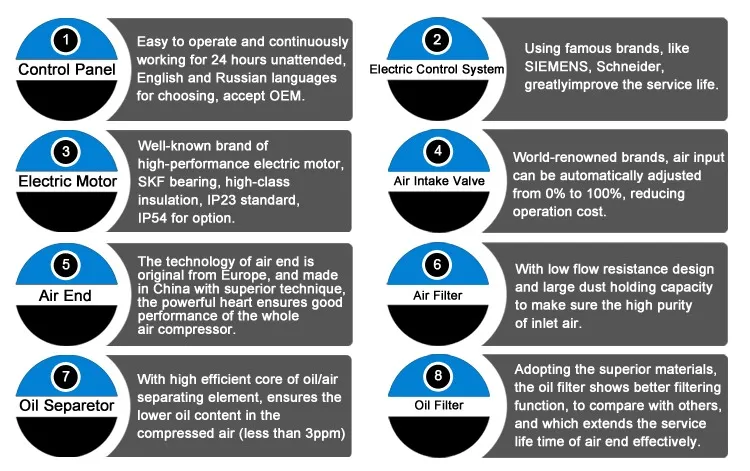

1.Motor: With the tailor-made low RPM motor and the isolation rate F SKF bearings, our compressors are ensured to operate reliably and are 3% to 5% more efficient than competing machines.

2.Air End: By using the most advanced 3rd generation 5:6 rotors and the optimized rotor profile from Europe, our air-ends are the best-in-class with low noise, low energy consumption, low maintenance cost, and long reliable service life.

3.Oil Filter: Adopting the aerospace design revolving oil filter with superior materials, our oil filters show a better filtering result than other oil filters and effectively extent the service life of air-ends.

4.Air Filter: By using the large dust holding and low flow resistance design, our air filters can filter the micro articles in the air to ensure every component of the system works normally and efficiently. The dust holding rate is over 99.5%.

5.Air Inlet Valve: With the design, the inler valve can be adjusted between 0 to 100%. By using the volume, adjustment valve, the compressors will loss less pressure and have a longer service life.

6.Oil-Air Separator: With the super high volume tank, the superior quality separator components, and the advanced design thrice oil-air separator, our compressors can ensure the high quality of the compressed air which contains less than 3ppm oil.