air compressor for laser cutting machine

air compressor for laser cutter | laser cutter air compressor | laser machine air compressor

Micro-oil 1.8MPa pressure permanent magnet variable frequency screw air compressor

- Pressure 18 kg: laser cutting speed increased by 50%,smooth and no burrs.

- Stable and reliable: It adopts the energy-saving main engine with large screw, low speed and double-acting opposing compression cavity, and adopts heavy-duty bearing: the equipment is more reliable and stable, and the performance of the whole machine isimproved by more than 20%.

- The equipment runs smoothly and has low noise: the double-acting opposed compression cavity energy-saving host has lower operating vibration and will not fall down even if you set up a coin. Quiet operation, can be installed on site, saving high pipeline fees.

- Oil content≤2PPM: The same filter has better effect, ensuring that the laser head is not polluted and has a long service life.

- There is also a 30 kg pressure laser cutting screw air compressor to choose from, allowing your laser cutting machine to release the maximum capacity.

A full set of professional laser cutting screw compressed air solutions let you rest assured! Make it go!

①Model with gas tank

|

Power frequency (permanent magnet frequency conversion) screw air compressor CMNZG11APV-1.8MPa |

|

|

Exhaust pressure(MPa) |

1.8 |

|

Exhaust flow(m³/min) |

0.7 |

|

Supply air temperature(℃) |

Ambient temperature +15℃ |

|

Gas supply oil content |

≤2ppm |

|

cooling method |

Air cooling |

|

Delivery method |

Direct coupling |

|

Lubrication method |

Fuel injection |

|

Noise(dB(A)) |

62 |

|

Main motor power |

11kW |

|

Fan motor power |

150W |

|

Dimensions (mm) |

1100×680×1010 |

|

Weight (kg) |

390 |

|

Outlet size |

1″ |

|

Start method |

Star-delta start (frequency conversion start) |

|

Freeze dryer parameters |

||

|

Model/Specification |

CMNL-5F |

|

|

Specification: |

||

|

Fixed work stress |

≤1.0Mpa |

|

|

Rated capacity |

0.7m3/min |

|

|

Maximum intake air temperature |

≤85℃ |

|

|

Dew point of compressed air after treatment |

2~10℃ |

|

|

Compressed air inlet and outlet |

RC1″ |

|

|

Cooling method |

Air cooling |

|

|

Dimensions L×W×H |

500×300×545mm |

|

|

Net weight |

25kg |

|

|

Voltage |

220V/50HZ |

|

|

Filter parameters |

|||

|

Model/Specification |

C/T/A/E-001 |

Quantity |

4pc |

|

Detailed parameters of main pipe dust filter: |

|||

|

Fixed work stress |

≤1.0MPa |

||

|

Rated capacity |

1.6m3/min |

||

|

Compressed air inlet and outlet connection size |

Rc1″ |

||

|

Horizontal carbon steel gas storage tank |

||

|

Model/Specification |

Q=0.36m³ P=1.8MPa |

|

|

Work pressure |

1.8MPa |

|

|

Set temperature |

150℃ |

|

|

Container inner diameter |

Φ550mm |

|

|

Container length |

1675mm |

|

|

Air outlet |

Rc3/4" |

|

②Model without gas tank

|

Power frequency (permanent magnet frequency conversion) screw air compressor CMNG11APV-1.8 |

|

|

Exhaust pressure(MPa) |

1.8 |

|

Exhaust flow(m³/min) |

0.7 |

|

Supply air temperature(℃) |

Ambient temperature +15℃ |

|

Gas supply oil content |

≤2ppm |

|

cooling method |

风冷 |

|

Delivery method |

Direct coupling |

|

Lubrication method |

Fuel injection |

|

Noise(dB(A)) |

62 |

|

Main motor |

11 |

|

Fan motor |

150W |

|

Dimensions (mm) |

1100×680×1010 |

|

Weight (kg) |

390 |

|

Outlet size |

1/2″ |

|

Start method |

Star-delta start (frequency conversion start) |

|

Freeze dryer parameters |

||

|

Model/Specification |

CMNL-5F |

|

|

Specification: |

||

|

Fixed work stress |

≤1.0Mpa |

|

|

Rated capacity |

0.7m3/min |

|

|

Maximum intake air temperature |

≤85℃ |

|

|

Dew point of compressed air after treatment |

2~10℃ |

|

|

Compressed air inlet and outlet connection caliber |

RC1″ |

|

|

cooling method |

Air cooling |

|

|

Dimensions L×W×H |

500×300×545mm |

|

|

Net weight |

25kg |

|

|

Voltage |

220V/50HZ |

|

|

Filter parameters |

|||

|

Model/Specification |

C/T/A/E-001 |

Qty |

4pc |

|

The detailed parameters of the main line dust filter: |

|||

|

Fixed work stress |

≤1.0MPa |

||

|

Rated capacity |

1.6m3/min |

||

|

Compressed air inlet and outlet connection size |

Rc1″ |

||

Two-stage compression micro-oil 3.0MPa screw air compressor

| Screw air compressor CMN18G-3.0MPa Specification: | ||

| Rated exhaust pressure | 3.0 | Mpa |

| Rated displacement | 1.73 | m3/min |

| Rated power | 18.5 | kW |

|

Drive way |

Secondary direct connection |

Coupling connection |

| cooling method | Air cooling | |

|

Outlet temperature |

≤ Ambient

temperature +25 |

℃ |

| Noise | 65 | dB(A) |

| Gas supply oil content | ≤2 | PPM |

|

Dimensions |

1650×1150×

1310 |

L×W×H(mm) |

| Total weight | 868 | Kg |

| Rated working power | 3/380/60 | PH/V/HZ |

| Start method | Y-△ | |

| Motor protection level | IP54 | |

|

Insulation class |

Class F

insulation |

|

|

Screw air compressor CMN22G-3.0MPa Specification: |

||

| Rated exhaust | 3.0 | Mpa |

| pressure | ||

|

Rated

displacement |

2.10 |

m3/min |

| rated power | 22 | kW |

|

Drive way |

Secondary direct

connection |

(Coupling connection) |

|

cooling

method |

Air cooling |

|

|

Outlet

temperature |

≤ Ambient

temperature+25 |

℃ |

| Noise | 65 | dB(A) |

|

Gas supply

oil content |

≤2 |

PPM |

| Dimensions | 1650×1150×1310 | L×W×H(mm) |

| Total weight | 900 | Kg |

|

Rated working

power |

3/380/60 |

PH/V/HZ |

| Start method | Y-△ | |

|

Motor protection level |

IP54 |

Class F insulation |

1.6MPa pressure oil-free screw air compressor

|

Oil-free screw compressor CM22BF-1.6 Specification: |

||

|

Rated exhaust pressure |

1.6 |

MPa |

|

Rated displacement |

2.40 |

m3/min |

|

Rated power |

22 |

kW |

|

Exhaust oil content |

0 |

PPM |

|

Cooling method |

Air cooling |

|

|

Noise |

65 |

dB(A) |

|

Dimensions |

1900×1000×1635 |

L×W×H(mm) |

|

Compressed air interface size |

1" |

|

|

Total weight |

1000 |

Kg |

|

Rated working power |

3/380/60 |

PH/V/HZ |

|

Start method |

Y-△Start |

|

| Permanent magnet variable frequency oil-free screw compressor CM22PVF-1.6 Specification: | ||

| Rated exhaust pressure | 1.6 | MPa |

| Rated displacement | 2.40 | m3/min |

| rated power | 22 | kW |

| Exhaust oil content | 0 | PPM |

| Cooling method | Air cooling | |

| Noise | 65 | dB(A) |

| Dimensions | 1900×1000×1635 | L×W×H(mm) |

| Compressed air interface size | 1" | |

| Total weight | 1000 | Kg |

| Rated working power | 3/380/60 | PH/V/HZ |

|

Start method |

Frequency conversion start |

|

The following is a comparison chart of the cutting effect under 18, 16, 13 kg pressure

The relationship between the pressure of the laser cutting machine and the thickness of the cut sheet

|

Maximum cutting speed of laser cutting machine power

80000mm/min |

||||

|

Pressure |

12 |

16 |

18 |

25 |

|

Carbon steel thickness |

1 |

2 |

3.5 |

4.5 |

|

Stainless steel

thickness |

2 |

6 |

8 |

10 |

Advantages

- Motor

1.IEC high efficiency drive motor

2.IP54 and high temperature F class rating

- Controller

1.Easy to use and maintenance free

2.Constant readout of pressure and temperature

3.Provides 24 hours automatic start-stop operation

- Inlet valve

The unique design differential pressure valve provide rapid response under any condition and maintains the set differential pressure between the inlet pressure and outlet pressure.100% modulating inlet valve to match system air demand.

- Filtration system

Ultra efficient Kerry inlet air filters provide clean air that traps dirt particals to less than 3 microns.

- Electrical control protection

1.Phase protectiom

2.Phase sequence protection relay

3.High discharge temperature shutdown

4.Auto-dual control

5.Overload start protection

Specifications

| Model | Working pressure | Air deilivery | Motor power | Dimension(mm) | Weight(kg) | Output pipe diameter | ||

| psi | bar | cfm | m3/min | kw/hp | ||||

| BK7.5 | 116 | 8 | 43 | 1.2 | 7.5/10 | 1300×720×1650 | 200 | G3/4 |

| BK11 | 116 | 8 | 60 | 1.7 | 11/15 | 1000×670×1090 | 280 | G1 |

| 145 | 10 | 53 | 1.5 | |||||

| 188 | 13 | 42 | 1.2 | |||||

| BK15 | 116 | 8 | 85 | 2.4 | 15/20 | 1000×670×1090 | 290 | G1 |

| 145 | 10 | 78 | 2.2 | |||||

| 188 | 13 | 60 | 1.7 | |||||

| BK18 | 116 | 8 | 107 | 3 | 18/24 | 1200×800×1120 | 350 | G1 |

| 145 | 10 | 96 | 2.7 | |||||

| 188 | 13 | 82 | 2.3 | |||||

| BK22 | 116 | 8 | 128 | 3.6 | 22/30 | 1200×800×1120 | 390 | G1 |

| 145 | 10 | 114 | 3.2 | |||||

| 188 | 13 | 96 | 2.7 | |||||

| BK30 | 116 | 8 | 178 | 5 | 30/40 | 1320×850×1335 | 470 | G11/2 |

| 145 | 10 | 157 | 4.4 | |||||

| 188 | 13 | 128 | 3.6 | |||||

| BK37 | 116 | 8 | 214 | 6 | 37/50 | 1320×850×1330 | 560 | G11/2 |

| 145 | 10 | 196 | 5.5 | |||||

| 188 | 13 | 164 | 4.6 | |||||

| BK45 | 116 | 8 | 253 | 7.1 | 45/60 | 1240×1030×1595 | 700 | G11/2 |

| 145 | 10 | 232 | 6.5 | |||||

| 188 | 13 | 200 | 5.6 | |||||

| BK55 | 116 | 8 | 339 | 9.5 | 55/75 | 1540×1200×1470 | 895 | G11/2 |

| 145 | 10 | 303 | 8.5 | |||||

| 188 | 13 | 264 | 7.4 | |||||

| BK75 | 116 | 8 | 464 | 13 | 75/100 | 1800×1190×1710 | 1210 | G2 |

| BK90 | 116 | 8 | 571 | 16 | 90/120 | 1800×1190×1710 | 1240 | G2 |

| BK110 | 116 | 8 | 714 | 20 | 110/146 | 2100×1230×1730 | 1680 | DN65 |

| BK132 | 116 | 8 | 785 | 22 | 132/176 | 2100×1230×1730 | 1740 | DN65 |

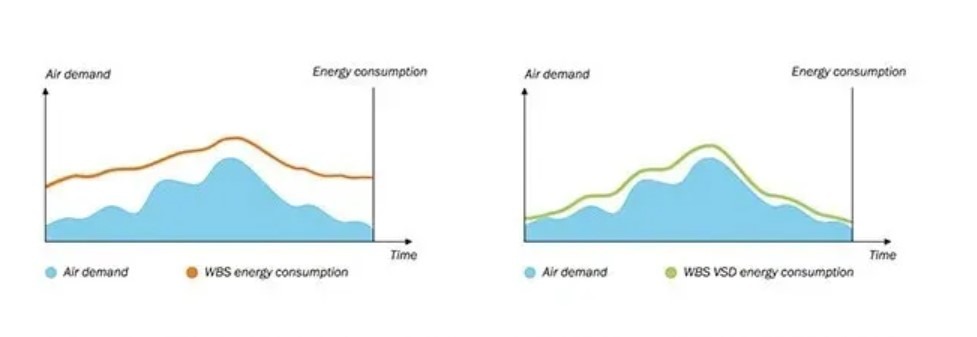

VSD range screw air compressor is equipped with higher efficiency airend, permanent magnet frequency motor and inverter, it can save on average 35% energy comparing to WBS range. Moreover, the generationof compressed air can account for more than 40% of plant’s toltal electricity bill

Features

1.On average 35% energy saving during fluctuations in production demand with an extensive turndown range

2. Intelligent controller controls the motor speed and high efficiency frequency inverter.

3. No wasted idling times in normal operation

4. Elimates peak current penalty during start-up

From the graphics above, it is easy to see the energy consumption fluctuates for WBS VSD range is close to the air demand variety. it saves more energy than WBS rang.

WBS VSD range compressors closely follow the air demand by automatically adjusting the motor speed

the results in on average of 35% energy saving.

Laser Cutting Screw Air Compressor

With the development of technology, more and more metal machining companies have chosen to use laser cutting machines. Laser cutting machines must be equipped with high quality,high pressure,low water vapor air compressors. To this end, DLOL compressors are specially desighed for laser cutting machines with 16bar combined permanent mangent variable frequency screw machine, which integates a permanent magnet variable frequency screw compressor,a cold dryer, a air tank, a high efficiency filter and an electronic drain value. It can directly outpet high-quality 16bar compressored air,which is perfectly matched with laser cutting machine.

|

Laser Cutting Screw Air Compressor

|

||||

|

Model

|

Pressure(Mpa)

|

Displacement(m3/min)

|

Power(KW/HP)

|

Weght(KG)

|

|

GRF-10LCT

|

1.6Mpa

|

0.5

|

7.5/10

|

450

|

|

GRF-15LCT

|

0.85

|

11/15

|

480

|

|

|

GRF-20LCT

|

1.3

|

15/20

|

500

|

|

|

GRF-25LCT

|

1.8

|

18.5/25

|

550

|

|

|

GRF-30LCT

|

2.3

|

22/30

|

580

|

|