PET Blowing Industry

PET Air Compressor

High-pressure air compressor for PET Blowing

Not PISTON

No more high noise and vibration

SCREW TYPE

Patented two-stage single screw compression

Not BOOSTER

No more high maintenance costs

We have more than 30 years’ experience.

PET (polyethylene terephthalate) is known to be a safe and recyclable packaging material. PET containers are more environmentally friendly and cost-effective than aluminum cans and glass bottles.

Air compressors are the leading equipment in plastic processing plants and require large amounts of compressed air to blow PET or PP preforms into bottles.

Typical Applications for PET Air Compressor

PET Bottle blowing

High-pressure compressed air is used for bottle-blowing.

Pressure depends on vessel design, wall thickness, blowing speed, etc. Bottles with thick walls, sharp edges, and unique shapes require higher pressures. Generally, stretch blow molding requires a pre-blowing process of about 10~25bar and a blow molding process of about 40bar. The trend in PET blow molding machines is to reduce blowing pressure as much as possible to save energy.

Cleaning

Compressed air should be used to clean the bottle before filling water, beverages, cooking oil, etc.

If the air is polluted, it can affect the sense of taste and smell, leading to health problems.

Filling

Liquid dose filling machines should use oil-free compressed air.

Packing and labeling

Low-pressure compressed air is also used in automated production lines such as packaging and labeling.

Instrumentation

For pneumatic conveying during manufacturing.

For control valve, sorting, polishing, etc.

Development for PET Air Compressor

Compressor solutions for PET blow molding machines are as follows:

| Comparison | Small Oil-lubricated Piston | Oil-free Piston | Booster | Oil-free SCREW |

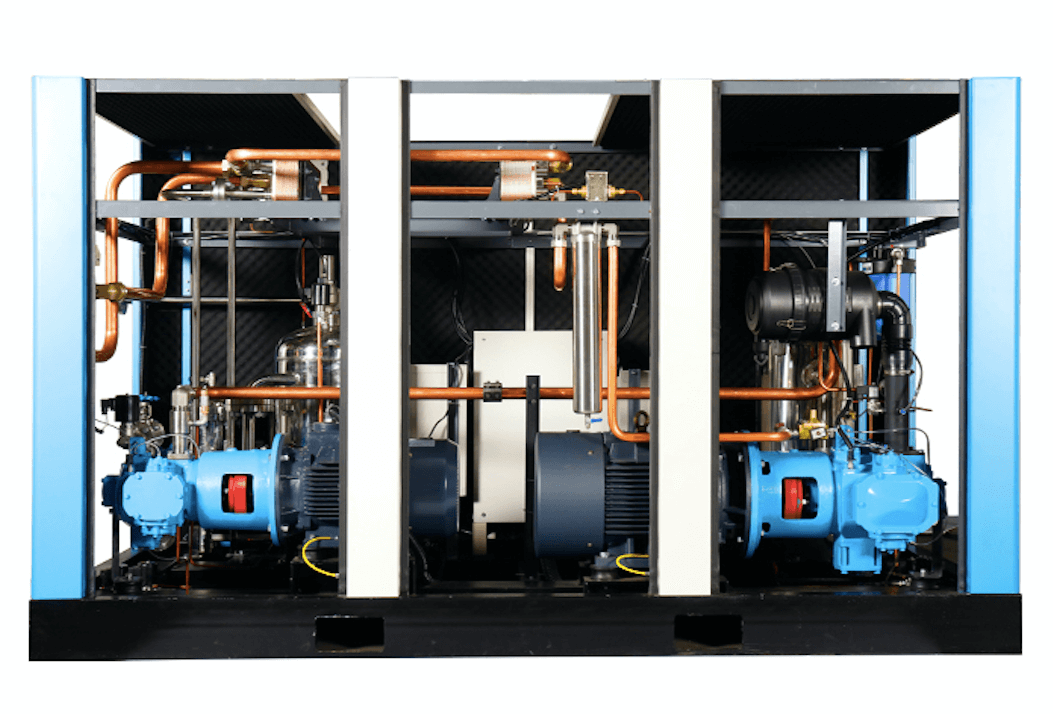

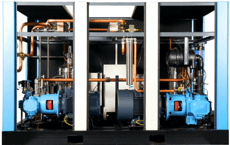

| Photo |  |

|

|

|

| Lubricate method | Oil-lubricated | Oil-free (Class 1) | Oil-free (Class 1) | 100% Oil-free (Class 0) |

| Cooling method | Air-cooled | Water-cooled | Water-cooled | Air-cooled or Water-cooled |

| Compression stages | Two-stage/Three-stage piston | Three-stage piston | 1st screw 2nd piston | Two-stage SCREW |

| Space for 40bar 6m3/min | 3800*1000*1700mm 2800kg | 3100*1750*2150mm 3400kg | 2790*1500*1470mm 3200kg | 2900*1400*1700mm 2100kg |

| Comparison | Piston type | Screw type |

| Working principle | A piston compressor compresses and cools the air in different cylinders. For example, atmospheric air is compressed to 4~5bar in the first cylinder, then cooled and pushed to 15~17bar in the second cylinder, then the air is cooled again and finally reaches 40bar. | Screw type, the compressed air of the first-stage screw is compressed to 7~8bar without cooling; the air enters the second-stage screw host, reaches 30~40bar, and is directly discharged without cooling. |

| Efficiency | Low-speed 600-1500r/min, many friction pairs, low efficiency High temperature: energy loss due to hot air emissions shorter component life |

Rotation speed 3000r/min, zero loads About 50℃, no heat waste Ideal isothermal compression |

| Maintenance | Complex structure installation requires exceptional technical support High maintenance cost if the routine inspection is not performed for 4000~6000 hours |

Simple and Balanced Construction 50,000 hours of service life for less than $500/year |

Why Should We Choose Screw Type Compressor

| Comparison | Oil-free Screw Air Compressor | Oil-free Piston Air Compressor |

|---|---|---|

| Air quality | 100% Oil-free | Air cylinder Oil-free, Crankcase has oil |

| Compression Method | 2 Stage Screw | 3 Stage Piston |

| Lubricating Medium | Pure Water | None |

| Temperature | Low: < 55℃, No need for cooling | High: 125~200℃, After cooling about 60℃ |

| Cooling Method | Air Cooled or Water Cooled (Only one cooler for lubricating water) | Water Cooled (Two interstage coolers and one aftercooler for compressed air) |

| Rotate Speed | 3000 r/min Ideal Speed | 600~900 r/min Low Speed |

| Vibration and Noise | Balance and Simple structure, low vibration, and less noise | The pistons rise and fall or move back and forth, causing too much vibration and Noise |

| Costs – Purchasing | More | Less |

| Costs – Foundation | No costs | Require foundation and grouting due to high unbalanced forces & high vibration. |

| Costs – Maintenance | Only Air filter elements and Water filter elements | High wear & tear of moving parts like piston rings, valves, etc. |

| Costs – Energy (e.g. 40bar 10m3/min) | Motor Power: 112kW (1st stage 75kW+2nd stage 37kW) | Motor Power: 132kW |

| Capacity Loss | There is no loss / very minor loss in Capacity over a period. | There is De-ration in Capacity due to wear and tear in cylinder crankcase, piston rings, pistons, and valves. |

Quality Requirements for PET Air Compressor

In general, compressed air should be cleaned of contaminants before use. Common contaminants are solid particles, water vapor and moisture, and oil vapor. Mainly used for the distribution of lubricating oil, pipelines, air storage tanks, atmospheric pressure, and oil-injected air compressors.

When PET compressed air is directly connected to drinking water or beverages and edible oils, purity and cleanliness must be guaranteed to prevent contamination. Specifically, what we should do is as follows:

Remove the moisture

Moisture is known to favor the growth of microorganisms and fungi. If there is moisture in the compressed air line, it can easily be blown onto the product or packaging, or container. So we need to use a dryer to guarantee the desired dew point. Generally, the dew point of compressed air in direct contact is -40°C, and a desiccant dryer is used. Low-risk non-contact compressed air has a dew point of 3°C and uses a refrigerated air dryer.

Remove the oil

There is oil in the atmosphere, so even if you choose a 100% oil-free air compressor, there is still oil vapor in the compressed air, so you should use a filter.

In general, oil-free air compressors must be used for compressed air in direct contact. Ensures Class 0 100% high purity oil-free compressed air, eliminating the health risks of rejection risks associated with oil contamination. For low-risk non-contact compressed air, we can use more economical oil lubricated air compressors, but it is best to use a filter to ensure 0.003ppm oil content.

Remove the particles

The atmosphere contains solid particles or dust that may cause contamination if in contact with the product. Other contaminants can come from the internal mechanisms of the air compressor system. We also need to use a filter to ensure that the particle content does not exceed 0.01μm.

Common Equipment for the Pharmaceutical/Medical Applications

For compressed air in direct contact with the production line, we recommend a 100% oil-free air compressor with a desiccant air dryer, filter, and food-grade stainless steel.

For non-contact, low-risk compressed air for production lines, oil-lubricated air compressors with refrigerated air dryers and filters can be an option if you are on a budget. Still, oil-free air compressors can not only be more affordable in the long run. Low maintenance and energy costs produce high-quality, oil-free, clean air.