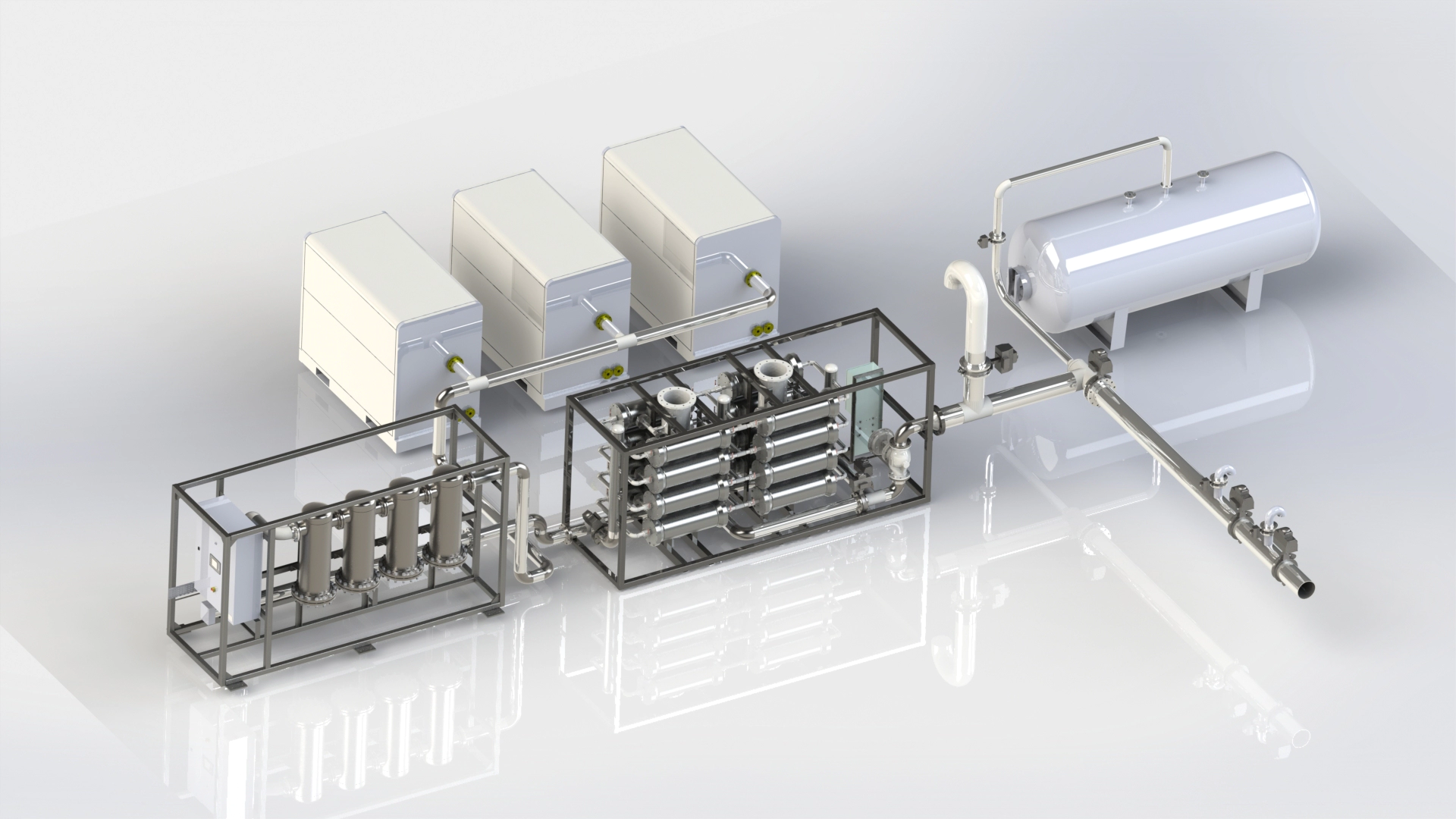

Gas Generator

Air Compressor for Gas Generator

Many industries have multiple needs for the continuous supply of high-purity gases such as oxygen and nitrogen.

These gases are transported on-site in cylinders. However, it has several disadvantages, such as delivery costs, waiting times, supply constraints, and contamination risks.

As a result, industries are now turning to better, safer, and cheaper solutions such as on-site gas generators.

One of the main components of a gas generator is the air compressor. Let’s deeply dive into how air compressors work in the gas generator industry.

Do you need

Do you need

for your oxygen/nitrogen generating line?

Tenemos más de 30 años de experiencia.

Air Compressor in a Gas Generator

Most on-site gas generators require an air compressor to work. Among the compressors, oil-free screw air compressors are the most reliable and energy-efficient. Also, they are quiet and require low maintenance.

Oil-free screw air compressors can perform a variety of functions, including:

Air pressure is increased to the level required by the nitrogen or oxygen generation system through a pressure swing adsorption (PSA) system or membrane.

Increase the pressure of the output gas to the desired level, usually in a VPSA oxygen generator.

Depending on your pressure and airflow requirements, you can use four types of oil-free screw air compressors with your gas generator.

The types are as follows:

2~5bar oil-free screw air compressor

30~40 bar oil-free screw air compressor

7~10bar oil-free screw air compressor

Super energy-saving series (8~40bar)

Air Compressor in Nitrogen Gas Generators

Air compressors are an essential part of nitrogen generators because these generators extract pure nitrogen from compressed air by separating it from oxygen and other gas molecules.

Pure nitrogen helps in many industrial applications, including removing oxygen and strengthening materials. It is also used in food packaging, chemical plants, electronics, pollution control, mining, pharmaceuticals, oil and gas, military, and aerospace.

Two main types of nitrogen generators use air compressors:

PSA Nitrogen Generator

Also known as a pressure swing adsorption (PSA) nitrogen generator.

Its multi-stage purification process makes it superior to membrane nitrogen generators. It provides 95% to 99.9995% purified output and consistent performance.

A typical PSA nitrogen generator consists of an air compressor, an inlet filter, a pair of carbon molecular sieves (CMS), an air dryer, a buffer tank, an outlet, a control valve, and a sensor.

The air compressor pressurizes the air, and the air dryer dries it. The inlet filter then removes impurities.

Next, the purified air enters the first-stage pressurized screen. The oxygen is separated at high pressure, leaving pure dry nitrogen. The dry nitrogen was then stored in a nitrogen buffer tank.

After the first-stage pressurized sieve is concentrated, it is regenerated under reduced pressure. At the same time, the purified air is switched to the second-stage pressurized screen for the denitration process.

Membrane Nitrogen Generator

The generator consists of an air compressor, inlet filter, dryer unit, air heater (optional), membrane, and nitrogen storage tank.

Air enters the air compressor through the air intake. It is compressed to the required pressure and sent to the inlet filter. These filters remove impurities from the air.

Next, the purified air passes through the hollow fiber membranes. Unwanted gases, including oxygen, diffuse at different rates depending on their molecular structure. This leaves behind heavier, slower-moving but pure nitrogen molecules. Pure nitrogen is then collected into a buffer tank for use.

These gas generators are compact, quiet, and efficient. But they can only produce 95% to 99.9% pure nitrogen at a slower rate.

Air Compressor in Oxygen Generators

Oil-free screw air compressors are also essential for oxygen generators. Industries use these on-site oxygen generators to increase their productivity and efficiency. They are also safe and cost-effective.

Three main types of oxygen generators use air compressors:

Pressure Swing Adsorption (PSA) Oxygen Generators:

The working principle of the PSA oxygen generator is similar to that of the pressure swing adsorption nitrogen generator. It uses an absorbent material like zeolite as a sieve to extract pure oxygen from compressed air. This technology produces 90-99% oxygen-containing gas.

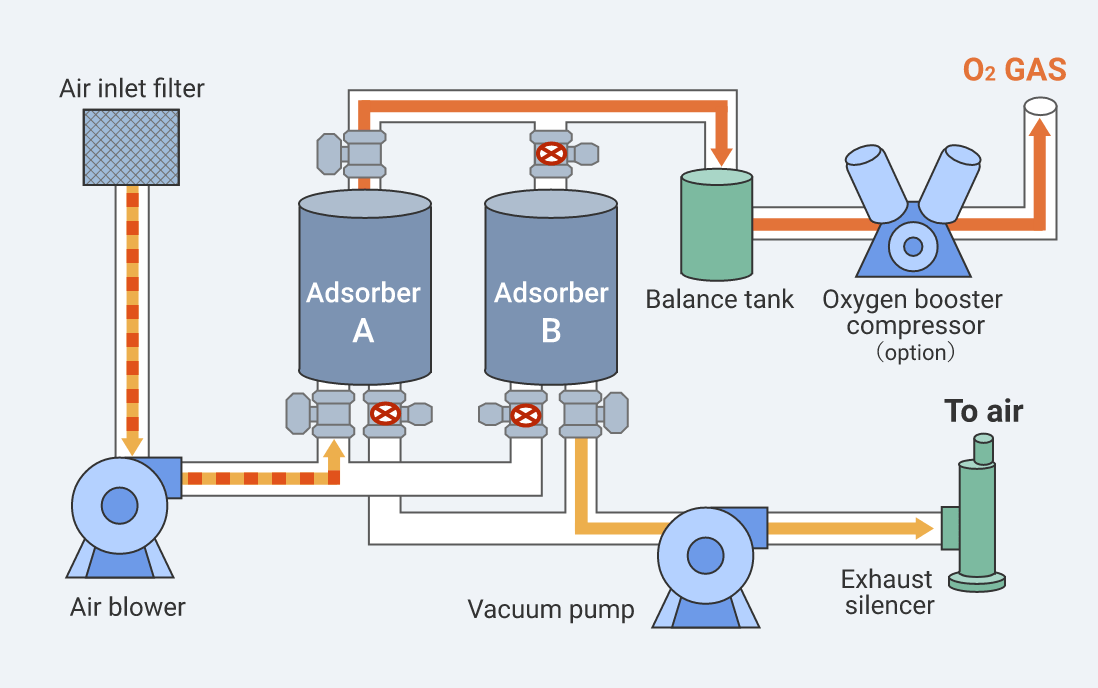

VPSA Oxygen Generator

These oxygen concentrators use vacuum swing absorption technology that uses a blower instead of an air compressor to bring less compressed air into the system. In addition, the vacuum pump sucks the exhaust gas and assists in the regeneration process of the screen.

You can also use a 7~10bar oil-free screw air compressor as an oxygen booster. It is to output oxygen to obtain a higher oxygen pressure. This technology produces 90-95% oxygen-containing gas.

VPSA oxygen generator includes a blower, air filter, air cooler, muffler, carbon molecular sieve (CMS), vacuum pump, oxygen buffer, and oxygen booster compressor.

The air is passed through a series of filters to remove impurities. Blowers and air coolers then compress and condition the air.

The purified air is then sent to one of the absorption towers containing zeolite as a screen. Here, the surface of the zeolite absorbs nitrogen from the air, leaving oxygen of the desired purity behind oxygen.

Once the nitrogen concentration in the first column is concentrated, a vacuum pump can be used for regeneration. The purified air is switched to another sieve for the same absorption process.

The purified oxygen is then compressed to the desired level by an air compressor and stored in a compressed oxygen buffer tank for output.

Membrane Oxygen Generator

They are considered a reliable oxygen production system with no moving parts that could fail.

The generator consists of an air compressor, inlet filter, dryer unit, membrane, and oxygen storage tank.

Air enters the air compressor through the air intake. It is compressed to the required pressure and sent to the inlet filter.

These filters remove impurities from the air. Next, the purified air passes through the hollow fiber membrane, and the oxygen diffuses at a certain speed according to its molecular structure, leaving other gases behind.

The oxygen is then filtered from the remaining gas and collected in an oxygen buffer tank.

These gas generators are compact, quiet, and efficient. But they can only produce 95% to 99.9% pure oxygen at a slower rate.

Common Equipment for the Gas Generator Applications

If nitrogen or oxygen is to be used in the food and medical industries, we recommend a 100% oil-free air compressor with a desiccant air dryer, filter, and food-grade stainless steel.

For low-risk compressed air in a production line, an oil-lubricated air compressor with a refrigerated air dryer and filter can be an option if you are on a budget. Still, in the long run, an oil-free air compressor can’t just produce high-quality Oil-to-air compressors and clean air, reducing maintenance and energy costs.