Aerospace Industry

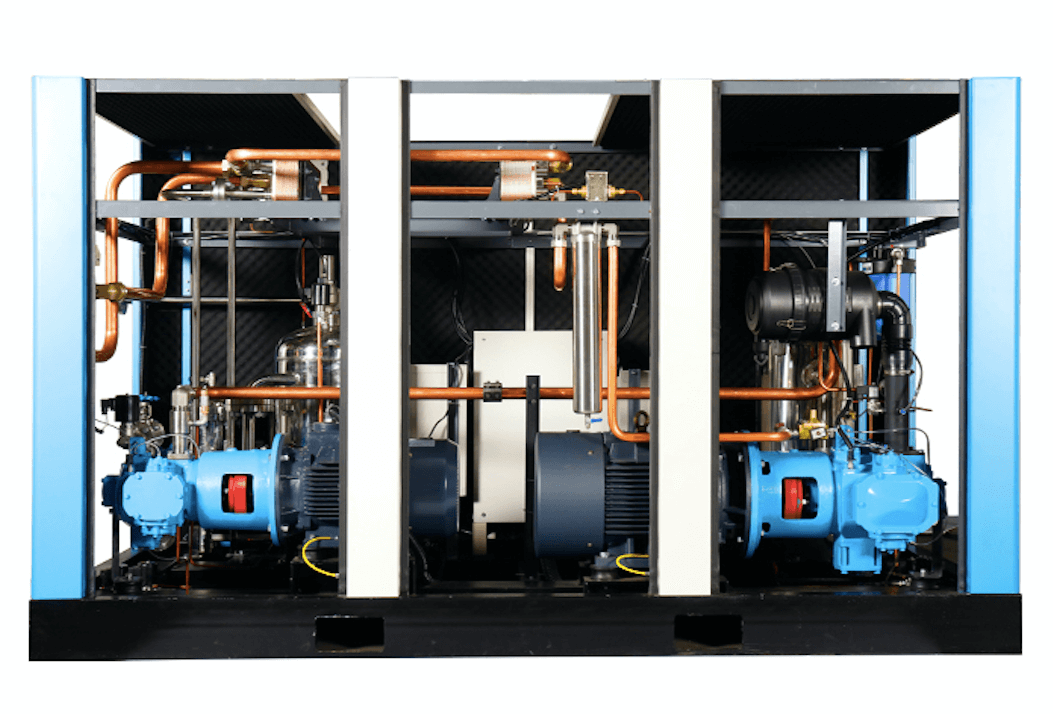

Air Compressor for Aerospace

High-pressure air compressor for Aerospace

No PISTÓN

Se acabaron los ruidos y las vibraciones

TIPO DE TORNILLO

Patented Two-stage single-screw compression

No BOOSTER

Se acabaron los elevados costes de mantenimiento

Tenemos más de 30 años de experiencia.

Typical Applications for Aerospace Air Compressor

Screw air compressors play an essential role in manufacturing and flight control functions in the aerospace industry.

Air compressors maximize performance and safety and reduce pollution.

The following are the main applications of air compressors in the aerospace field.

Aircraft Engine Manufacturing

Industrial-themed view. Repair and maintenance of aircraft engines on aircraft wings

Aircraft engineers and manufacturers use air compressors in aircraft engines as an essential part of the engine’s core system.

The compressor has an air shaft where air enters the aircraft and flows through the fan.

The compressor fan raises the air pressure, increasing the air’s energy potential and moving the now compressed air to the combustion chamber.

Air compression is critical for aircraft manufacturing safety testing, as aircraft engines must perform at their best during flight.

Air compression is a simulation tool used to test engine performance and durability during manufacturing.

Ground Support Equipment

Airport. The airplane is being serviced by the ground crew.

Ground support equipment is used to maintain and facilitate aircraft operations between flights.

Ground support teams use hammers, grinders, and welding equipment to maintain operability.

The team uses air compressors to repair aircraft functions and components and generate cabin pressure.

The air starter produces a large volume of low-pressure air to start the engine for the next flight.

The air starter unit is equipped with a gas turbine unit, air receiver, and screw compressor unit to create optimum air pressure for engine function.

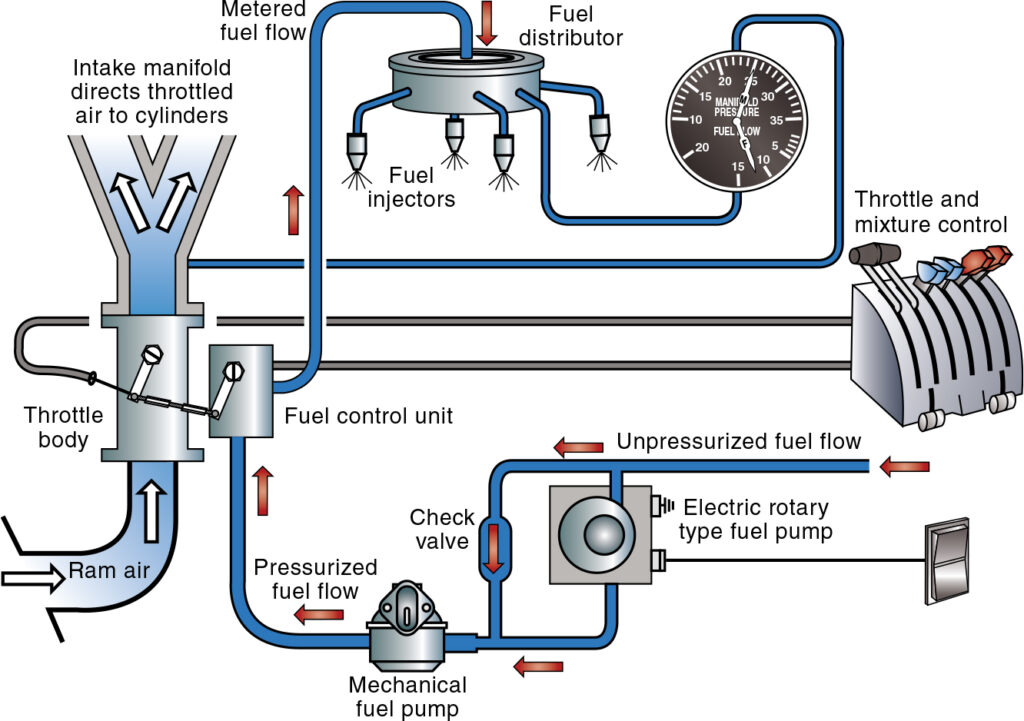

Fuel Injection Systems

The fuel injection system runs the aircraft and uses the fuel pump to flow engine fuel through the metering system, injector lines, and individual cylinders.

Fuel injection systems have no air to mix with engine fuel in the metering system; however, air compression plays a vital role in system operation.

Aircraft engineers use air compressors to deliver fuel into engine cylinders to ensure that aircraft engines operate with a steady supply of fuel on long flights.

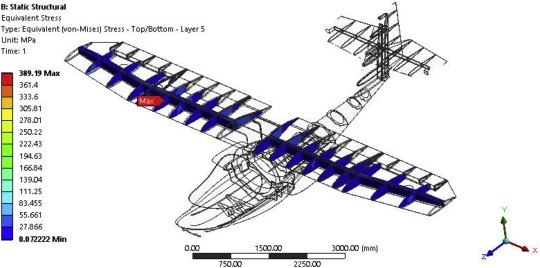

Wing Structural Testing

Aircraft wing structures are tested through simulations and air compression tests.

Engineers use air compressors to test different wing components to assess their robustness, durability, and functionality.

Aircraft engineers especially need to test the durability of the slats during catapult takeoff and stationary landing.

Slats are movable control surfaces that control high-velocity airflow to high-energy air or boundary layers.

As the slat extends forward, the gap between the wing slat and the leading edge causes high-energy air to enter the boundary layer at the top of the wing.

Engineers build wings that use high-pressure engines to direct air over the surface of the slats to create boundary control air.

Cabin Air Pressurization

The cabin pressurization system was invented to ensure that crew members and passengers can breathe easily at high altitudes.

Previously, piston-powered aircraft used electric air compressors to pump outside air into the cabin to create cabin pressurization.

Today, aircraft exhaust air from engines and turbo compressors and divert the air to the cabin area to create air pressure.

Hot exhaust gas from the engine compressor and combustion chamber flows through the intercooler to become ambient air, which is further cooled by airbags and an air circulation machine.

The air compresses the process air and dissipates the heat outdoors, where it expands and cools in an expansion turbine.

The cooling air is combined with the circulating air in the cabin through a fan, and the air entering the aircraft is regulated through an automatic outflow valve to maintain cabin pressure.

¿Por qué elegir un compresor de tornillo?

30~40bar Compresor de aire: Tornillo VS Pistón

| Comparación | Compresor de aire de tornillo sin aceite | Compresor de aire de pistón sin aceite |

|---|---|---|

| Calidad del aire | 100% Sin aceite | Cilindro de aire Sin aceite, El cárter tiene aceite |

| Método de compresión | 2 Etapa Tornillo | Pistón de 3 etapas |

| Medio lubricante | Agua pura | Ninguno |

| Temperatura | Bajo: < 55℃No necesita refrigeración | Alto: 125~200℃, Después de enfriar unos 60℃ |

| Método de refrigeración | Refrigeración por aire o por agua (sólo un refrigerador para el agua de lubricación) | Refrigeración por agua (dos refrigeradores interetapas y un refrigerador posterior para aire comprimido) |

| Velocidad de rotación | 3000 r/min Velocidad ideal | 600~900 r/min Velocidad baja |

| Vibraciones y ruido | Equilibrio y estructura simple, baja vibración y menos ruido | Los pistones suben y bajan o se mueven de un lado a otro, lo que provoca demasiadas vibraciones y ruido. |

| Costes - Compras | Más | Menos |

| Costes - Fundación | Sin gastos | Requiere cimentación y rejuntado debido a las elevadas fuerzas desequilibradas y vibraciones. |

| Costes - Mantenimiento | Sólo elementos filtrantes de aire y elementos filtrantes de agua | Gran desgaste de las piezas móviles como segmentos, válvulas, etc. |

| Costes - Energía (por ejemplo, 40bar 10m3/min) | Potencia del motor: 112 kW (1ª etapa 75 kW + 2ª etapa 37 kW) | Potencia del motor: 132 kW |

| Pérdida de capacidad | No hay pérdida / pérdida muy pequeña de Capacidad durante un periodo. | Se produce una desviación de la cilindrada debido al desgaste del cárter del cilindro, los segmentos, los pistones y las válvulas. |

Quality Requirements for Aerospace Air Compressor

In general, compressed air should be cleaned of contaminants before use. Common contaminants are solid particles, water vapor and moisture, and oil vapor. Mainly used for the distribution of lubricating oil, pipelines, air storage tanks, atmospheric pressure, oil-injected air compressors, etc.

When using compressed air in the aerospace industry, we must guarantee purity and cleanliness to prevent contamination. Specifically, what we should do is as follows:

Eliminar la humedad

Moisture is known to favor the growth of microorganisms and fungi. If there is moisture in the compressed air line, it can easily be blown onto the product, packaging or container. So we need to use a dryer to guarantee the desired dew point. Generally, the dew point of compressed air in direct contact is -40°C, and a desiccant dryer is used. Low risk non-contact compressed air has a dew point of 3°C and uses a refrigerated dryer.

Quitar el aceite

Hay aceite en la atmósfera, por lo que aunque elija un compresor de aire exento de aceite 100%, sigue habiendo vapor de aceite en el aire comprimido, por lo que debe utilizar un filtro.

In general, the compressed air in direct contact must use an oil-free air compressor. Ensures Class 0 100% high purity oil-free compressed air, eliminating the health risks of rejection risks associated with oil contamination. For low risk non-contact compressed air, we can use more economical oil lubricated air compressors, but it is best to use a filter to ensure 0.003ppm oil content.

Eliminar las partículas

La atmósfera contiene partículas sólidas o polvo que pueden causar contaminación si entran en contacto con el producto. Otros contaminantes pueden proceder de los mecanismos internos del sistema del compresor de aire. También debemos utilizar un filtro para garantizar que el contenido de partículas no supere los 0,01μm.

Common Equipment for the Aerospace Applications

For compressed air in direct contact with the production line, we recommend a 100% oil-free air compressor with a desiccant air dryer, filter and food grade stainless steel.

For non-contact, low-risk compressed air for production lines, oil-lubricated air compressors with refrigerated air dryers and filters can be selected if the budget is limited. Still, in the long run, oil-free air compressors can not only be more affordable with lower maintenance and energy costs, but also produce high-quality oil-free clean air.