Текстильная промышленность

Air Compressor for Textile Industry

Compressed air is an essential requirement of the textile industry nowadays. It allows low-cost operations in terms of energy consumption.

The air compressors are the pneumatic device. It converts chemical and electrical energy into potential energy in compressed air. An advancing textile industry works based on energy efficiency.

Therefore, it promotes cost-reducing techniques of using oil-free air compressors. There are multiple Applications of Air compressors in the textile industry to match modern needs.

Therefore choosing the best is the ultimate way to produce and process human-made or natural textile products.

Do you need

Do you need

for fewer rejections and better quality?

We have more than 30 years’ experience.

Application of Air Compressor In Textile

Air compressors have numerous applications in the textile industry. The fine yarn and vibrant color of the fabric are impossible without the air compressors in the industry.

1.Air-jet weaving

An air jet loom is a kind of weaving loom. The only difference is a loom without a shuttle. Instead, the air jets throw the weft yarn in the shed by the air compressors, consisting of the main nozzle, profile reed, and auxiliary nozzle.

Air-jet weaving transforms household fabrics like apparel of all kinds as well as industrial materials. Also possible are weaving plaids or jacquard fabrics. Air-jet looms have several advantages over shuttle weaving as they can process heavier yarns at a faster rate.

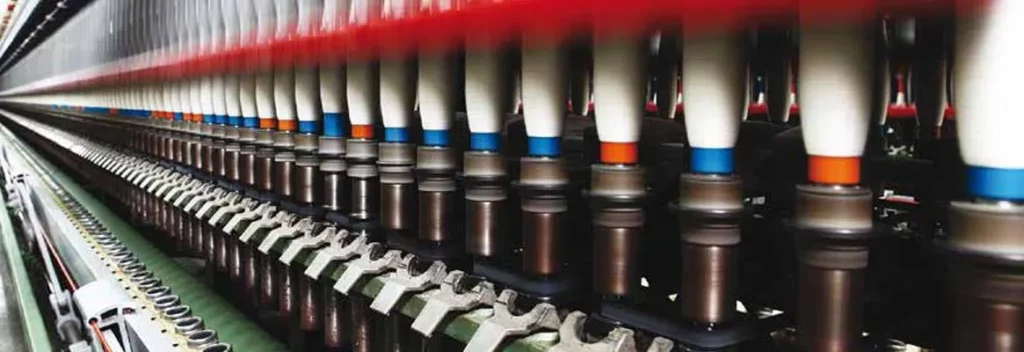

2.Spinning

The spinning of yarn and thread is an essential yet critical task. Hence air-jet spinning avoids the damage.

3 Texturizing

An air compressor generates a fast air jet through a nozzle to intermingle the yarn.

4 Pneumatic transport

Compressed air generated from air compressors also eases the pneumatic conveyor of fabrics and PET chips.

5 Artificial fiber production

The partially oriented yarn (POY) production and fully oriented yarn (FOY) need air compressors to produce compressed air.

6 Coning, winding, and dyeing non-woven textiles

Transporting the spinning yarn to a reel or cone is done with compressed air in textile industries.

7 Wastewater treatment

The yarn and thread production uses a lot of water with hazardous chemicals. The dying and other strengthening processes need chemicals to treat fabric and yarn to produce a quality fabric. Unfortunately, such wastewater is harmful to natural systems; therefore, air compressors are an essential part of wastewater treatment plants.

If you are associated with any of the above industries, you would likely need air compressors for your products. The problem you could face while buying is the quality and price of the air compressor. To solve your problem BENEAIR has a wide range of air compressors with good build quality and a reasonable price.

The Advantages of Air compressor in the textile industry

The correct types of equipment are vitally essential to meet the demands of the modern textile industry. In contrast, outdated devices and machinery will waste resources and produce quality compromised fabric and products. Therefore, using the latest techniques is an excellent opportunity to turn the challenge into a profit-generating moment.

High-Quality air compressors in the textile industry contribute to numerous competitive advantages. Here are some obvious benefits that you can attain using air compressors in the textile industry.

- Cost-effective operations

Compressed air assists textile manufacturers in overcoming various obstacles correlated with yarn and fabric production. The most significant factor among these benefits is cost-efficiency.

Good quality air compressors in the manufacturing unit ensure fast and efficient stock, adding competitive worth to the corporation itself.

- Increased productivity

Compressed air via air compressors also assists in supporting its tools and other maintenance equipment. It enables manufacturers to boost productivity rate and less time to mark the tremendous efficiency.

- Well managed waste production

Waste management utilizes the non-refundable resources of the industry. Therefore adding machinery that works using compressed air is a sustainable solution.

The Air compressors in the textile industry aim to decrease or productively regulate waste products.

Factors affecting Efficiency of Air compressor in textile industry

The Applications of Air Compressor in the textile industry is not replaceable with any other technique so far. Hence to enhance the efficiency and benefits of using the air compressors few factors play a vital role.

- Contaminated Air

A speck of dirt build-up inside the compressor can produce the contaminated compressed air. Therefore it requires regular cleaning and maintenance to work on the best form.

On the other hand, unattended machinery reduces the life span and efficiency with time.

- Humidity

Naturally, air contains water vapors. However, compressing becomes quite tricky and more energy-consuming because the air has a high level of humidity. Also, it can cause rusting of the metal parts of the compressor.

- Hot Air

Fortunately, cold air is convenient to compress. The colder air is already sufficiently compressed compared to hot air. Hence, it saves more time and resources to use cold air instead of hot air in air compressors.

Over the Horizon Applications of Air Compressor in textile industry

The textile industry has a high potential to absorb the latest techniques and replace traditional manufacturing systems. A minor cost-efficient shift regarding machinery affects the overall production cost to many folds.

Hence, the sophisticated and latest machinery helps the textile industry overcome the challenges. Simultaneously, it improves the quality of the textile products.

The future applications of Air Compressor in the textile industry have high potential as it tends to:

- Enhance the durability and potency to satisfy the desires of customers

- Reduction of production costs linked with operating and maintaining air compressor tools and systems

- Prevents flaws and contamination of air/fluid mixture in the production units

- Controls the excessive waste and perform a more sustainable operation in general

- Delays the aging and deteriorating production centers with modern equipment

The textile industry using compressed air is booming and flourishing like never before. Nevertheless, direct and indirect advantages run the textile industries at an optimum pace.

Common Equipment for the Textile Applications

If the compressed air is applied to the textile industry, we suggest using a 100% oil-free air compressor with a refrigeration air dryer and filters.

For a low-risk compressed air for production line, if with a limited budget, the oil-lubricated type air compressor with refrigeration air dryer and filters can be chosen, but for long-term consideration, an oil-free type air compressor can not only produce high-quality oil-free and clean air but also costs lower for maintenance and energy.