Dental Compressor

Dental Air Compressor

Air compressors are critical components in dental offices, hospitals, and laboratories and must be reliable and used daily. Therefore, we needed a low-noise, 100% oil-free air compressor to keep instruments clean and patients safe during dental procedures.

Clean compressed air is most widely used for cleaning, drying processes, and power tools. Typical applications include dental milling machines, autoclaves, disinfection, patient simulators, ENT air/vacuum aspirator, breathing equipment, oxygen concentrators, nebulizers, surgical instruments, and wheelchair tire inflation.

Do you need

for your Dental Chairs and tools?

Do you need

for your Dental Applications?

We have more than 30 years’ experience.

How to Choose The Right Dental Air Compressor

When choosing an air compressor for your dental practice, you should pay attention to the following factors:

Pressure

Evaluate and confirm all air pressure requirements for dental tools; the pressure you choose should be higher than the maximum air pressure you need. We should consider pressure loss/pressure drop. Most dental applications require about 5~6bar of pressure, and choose an air compressor of 7~8bar.

If the air pressure in the air compressor is lower than the pressure required by your tool, it can cause tool damage and injure your patient. For example, lower pressure reduces volume, and failure to drill or cut takes longer to treat your patient, which takes more time and makes your patient feel bad.

Airflow

As with air pressure, evaluate and confirm any airflow or volume requirements for the dental tool; the airflow you choose should be higher than the total airflow you need. As a rule of thumb, each dental chair requires approximately 50 l/min (50LPM or 2CFM) at 6 bar to meet the HTM 2022 standard. You should consider the number of chairs you are using simultaneously.

Strength

Most dental offices require 1~5hp oil-free air compressors to run dental tools, but the power will be higher for some larger dental offices.

Quality Requirements for Dental Compressor

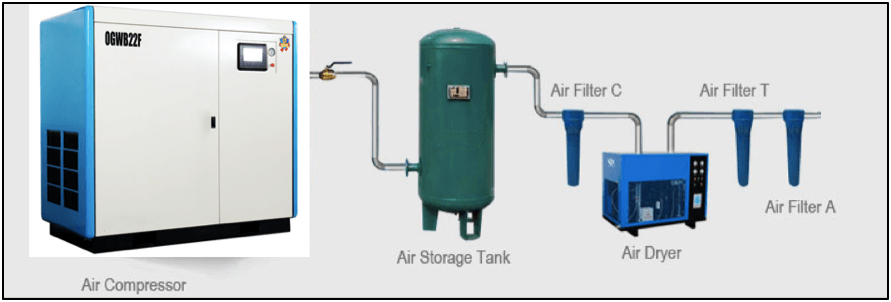

In the dental industry, compressed air should be cleaned of contaminants before use.

Common contaminants are solid particles, water vapor and moisture, and oil vapor. Mainly used for atmospheric pressure, oil-filled air compressor lubricating oil, pipelines, gas storage tanks, distribution, etc.

High-quality compressed air is safer for your patients.

Remove Moisture

The dew point of general dentist compressed air is -20°C~-40°C, use desiccant air dryer, low risk non-contact compressed air, the dew point is 3°C, use refrigerated air dryer.

Remove Oil

There is oil in the atmosphere, so even if you choose a 100% oil-free air compressor, there will still be oil vapor in the compressed air, so a filter should be used. Typically, for dental compressed air, a 100% oil-free air compressor must be used.

Remove Particles

The atmosphere contains solid particles or dust that can cause contamination if it comes into contact with food. Other contaminants can come from the internal mechanisms of the air compressor system. We also need to use a filter to ensure that the particle content does not exceed 0.01μm.