시멘트 산업

Air Compressor for Cement Industry

Air compression is an essential part of many cement mixing and manufacturing stages.

Air compressors and pneumatic conveyors enable efficient processing, reducing the workload, time, energy consumption, and pollution of the produced cement product.

Do you need

Do you need

We have more than 30 years’ experience.

Applications of Air Compressor in Cement Industry

Silo Control and Transport

The storage silo is located in the ready-mixed concrete mixing plant, and the fluidized powder is stored by the tank truck through pneumatic conveying.

The air compressor in the tanker uses exhaust control to pressurize the tanker and fluidize the powder in and around the tanker’s distribution plane.

The air compressor also plays a vital role in transporting the fluidized powder from the tanker to the pipeline to the cement silo.

Air is exhausted through filters in the silo to avoid damage to the machine, and if the air is poorly ventilated, consequences can include overpressure in the silo.

Overpressure can be a safety hazard and can damage plant equipment through silo explosions, damage to silo covers, and failure of filtration systems.

Ash Handling Systems

The combustion process in cement manufacturing produces ash that needs to be transported and loaded.

Fly ash handling systems are widely used in cement manufacturing and transport fly ash from thermal power stations to storage silos for cement manufacturing.

Cement plants use transmission air power in their air compression mechanisms to process and transport ash through smaller ash delivery pipes.

Air compression helps cement plants save space and energy consumption during ash handling.

Wet Process Clinker Plants

In the wet process, clinker plants and calcareous material are pulverized and argillaceous material is mixed with water.

The two materials are used in combination in the final stages of the cement manufacturing process.

Wet clinker plants use air compression to mix the raw materials in cement manufacturing.

The mixture becomes a “slurry” material and is sent to a cement kiln for further processing.

The raw meal is heat treated, calcined and linearized to produce clinker, which is then cooled in the next step.

Much energy is trapped in this cooled air, also known as combustion air, which enters the kiln for further clinker processing.

De-dusting

Air compression is used for dedusting in the cement industry, as the dedusting system in cement plants uses air compression for dedusting.

The specific gravity of the air in the intake pressure is distributed to the bags in the system through the pulse valve.

Pulse nozzles control the weight of compressed air, a critical step because dust collection systems require machine operators to provide accurate air pressure levels.

Dust collection systems require a specific flow of compressed air to operate effectively and to effectively repeat the dust collection process.

Baghouses in dust collection systems require regular monitoring to ensure reduced opportunities for corrosion and extended life of the overall system.

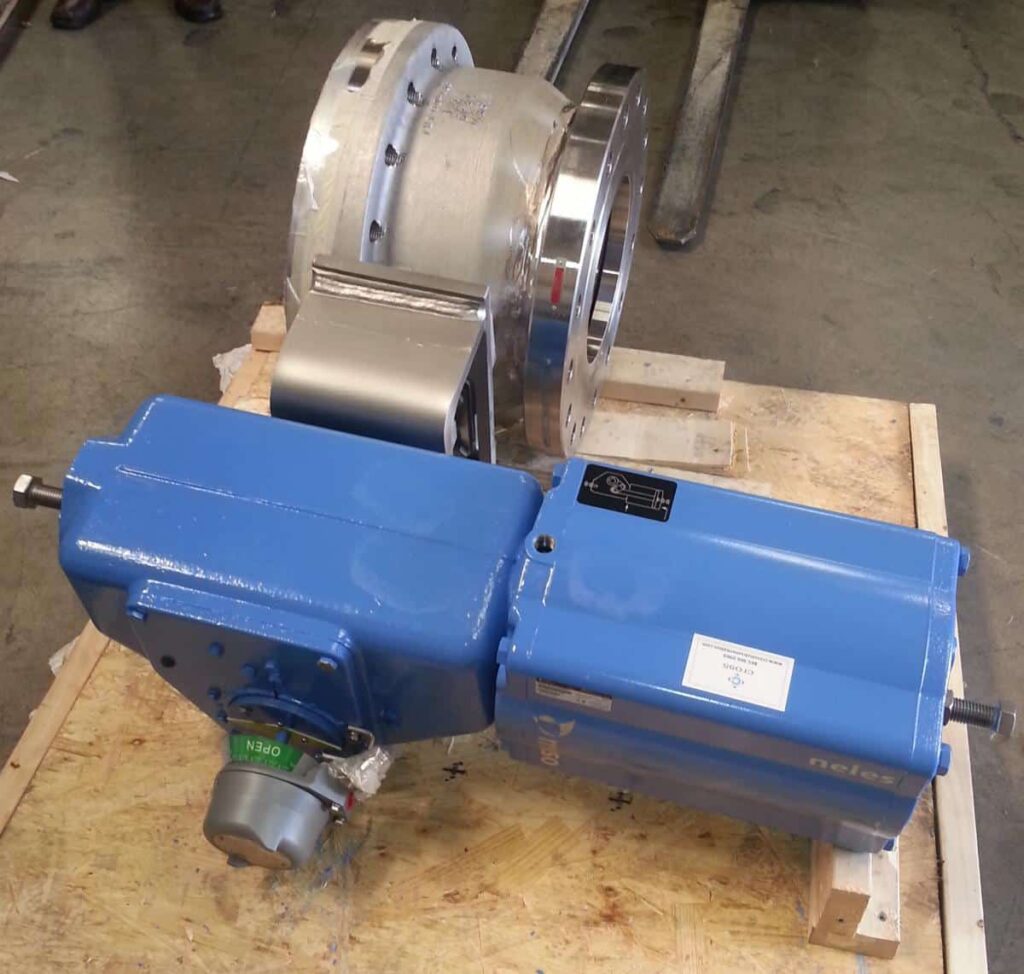

Pneumatic Actuators

Pneumatic actuators generate rotary or linear power by using air and pneumatic controls, and actuators are used to power the rotary motion of cement plant valves.

Compressed air is an integral part of pneumatic actuators and pneumatic controls in cement manufacturing.

Air compression must be optimal and free of contamination, as oil, dust, and water can rust and deteriorate pneumatic system processes.

Common Equipment for the Cement Applications

If compressed air is used in the cement industry, we recommend a super energy efficient secondary oil lubricated air compressor with air dryer and filter.

Regular single-stage oil-lubricated air compressors with refrigerated air dryers and filters can be selected if you are on a budget, but oil-free air compressors not only produce high-quality oil-free clean air for a long time, but also reduce cost and energy cost.