Electronic Industry

Electronic industry air compressor

Countless industries use air compressors for many applications, including powering various electrical and electronic equipment. They power a variety of power tools, including nail guns, pneumatic staplers, pneumatic sanders, and spray guns.

In addition to household and construction applications, compressed air also provides kinetic energy to pneumatic equipment, primarily used in electronics manufacturing, including pneumatic lathe chucks, pneumatic robotic arms, or other production equipment that transports or cools parts and pressure cleans parts during production.

Electronics manufacturing is a sensitive industry that requires high-tech machinery, highly skilled employees, a sterile environment, and strict production standards.

If the product gets into a printed circuit board (PCB) or other electronic components, the smallest amount of dust or other particles can damage the product.

Likewise, excess moisture on parts can cause failure or short circuits. All of this can be avoided thanks to the low impact and high energy conversion efficiency of compressed air.

Therefore, reliable air compressors have become the key to efficient and safe work in the electronics manufacturing industry.

Do you need

Do you need

for your electronic components?

We have more than 30 years’ experience.

Application of Air Compressor In Electronics

Here are some prominent applications of air compressors in the electronics industry and electronics manufacturing:

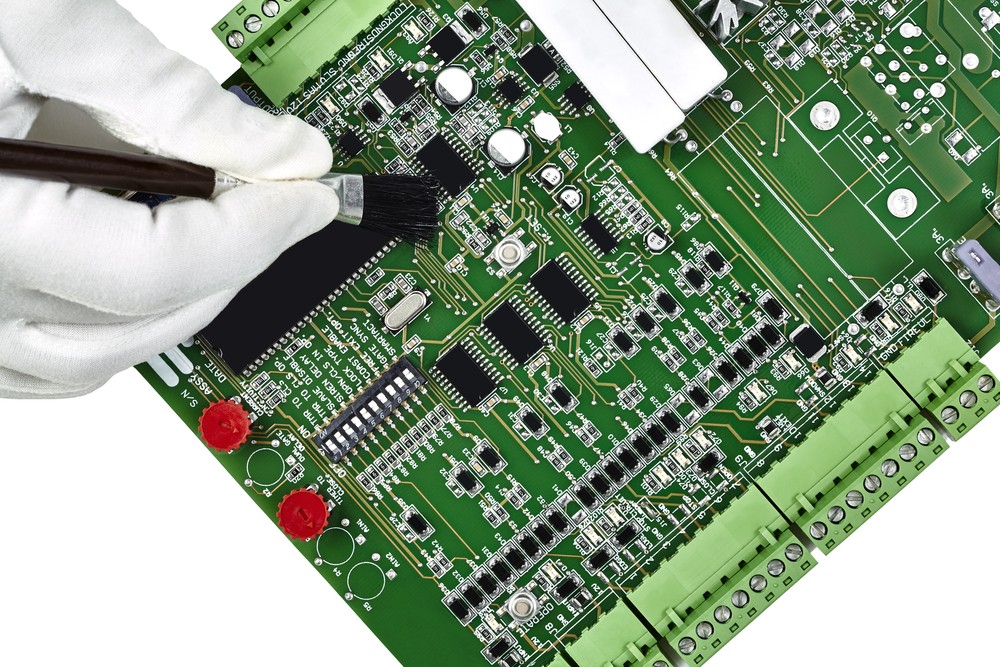

1 Printed circuit board (PCB) cleaning

Oil-free air compressors are used for printed circuit board (PCB) cleaning in the industry as they are clogging-free, low-impact, and wear-free.

It blows away dust and other unwanted substances from sensitive electronic components after production, leaving no oil stains in the form of liquids, aerosols and vapors.

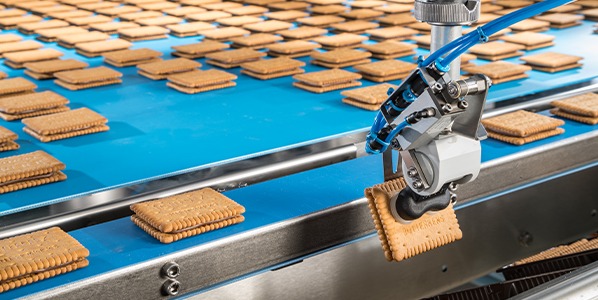

2 Pick and Place Machines

Pick and place equipment such as robotic machines (also known as pneumatic arms) for component handling are driven by air compressors.

A controlled amount of compressed air from an air compressor is delivered to specific parts of the robotic machine through a system of ducts. These components convert the potential energy of compressed air into mechanical energy for execution.

In many applications, air compressor driven pick and place equipment is preferred over electric, servo and hydraulic drive systems because of their light weight, robustness, safety and low hazard, high accuracy, low cost, ease of maintenance and extreme conditions , reduce the operating temperature.

3 Cable Pressurization

An air compressor helps maintain a specific pressure in the gas line. The air pressure allows the gas to continue down the pipe to the intended recipient. In addition, air compressors are also used to test and clean these pipes.

In addition to natural gas lines, air compressors are essential for maintaining underground telephone and TV cables. They allow the pressure inside the cable to be higher than the hydrostatic pressure outside the jacket.

Standing water puts pressure on underground cables (especially during storms), allowing water to seep into cracks in wires or junction boxes, causing electrolysis that can lead to faulty pairs within the cable.

Therefore, the air pressure through the air compressor protects the cable from moisture damage by maintaining a positive pressure within the cable. The positive pressure exceeds and counteracts the external force caused by the water.

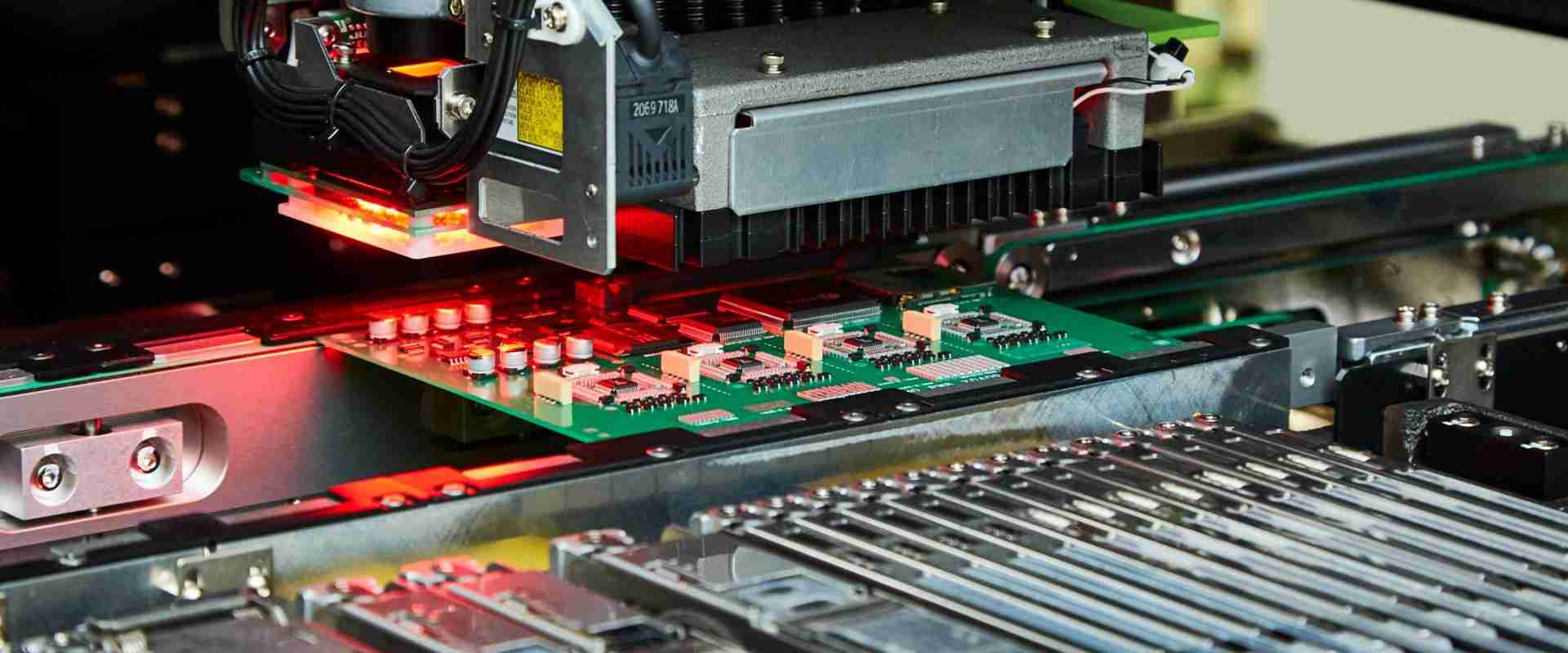

4 Surface Mounting Technology, Desoldering, and Test equipment

Air compressors are essential for SMT (Surface Mount Technology) component placement systems, also known as pick and place machines.

These systems place surface mount devices (SMDs), including resistors, capacitors, and integrated circuits, on PCBs (printed circuit boards) on printed circuit boards (PCBs).

Compressed air from the air compressor powers the pneumatic components of the SMT machine, including the flapper and cleat mechanism. They also power plate racks, nozzle changers, head pick and place, safety cover latches, pneumatic feeders, tubular feeders and mobile feeders.

They are also used in desoldering and testing equipment during PCB production.

5 Telescopic antennas

Telescopic antennas are used in telecommunications, broadcasting, surveillance, wind and solar production, disaster recovery, site surveys and site security.

The telescopic antenna uses an air compressor to raise its center post to extended height.

In addition, air compressors are used to de-ice mobile transmitters.

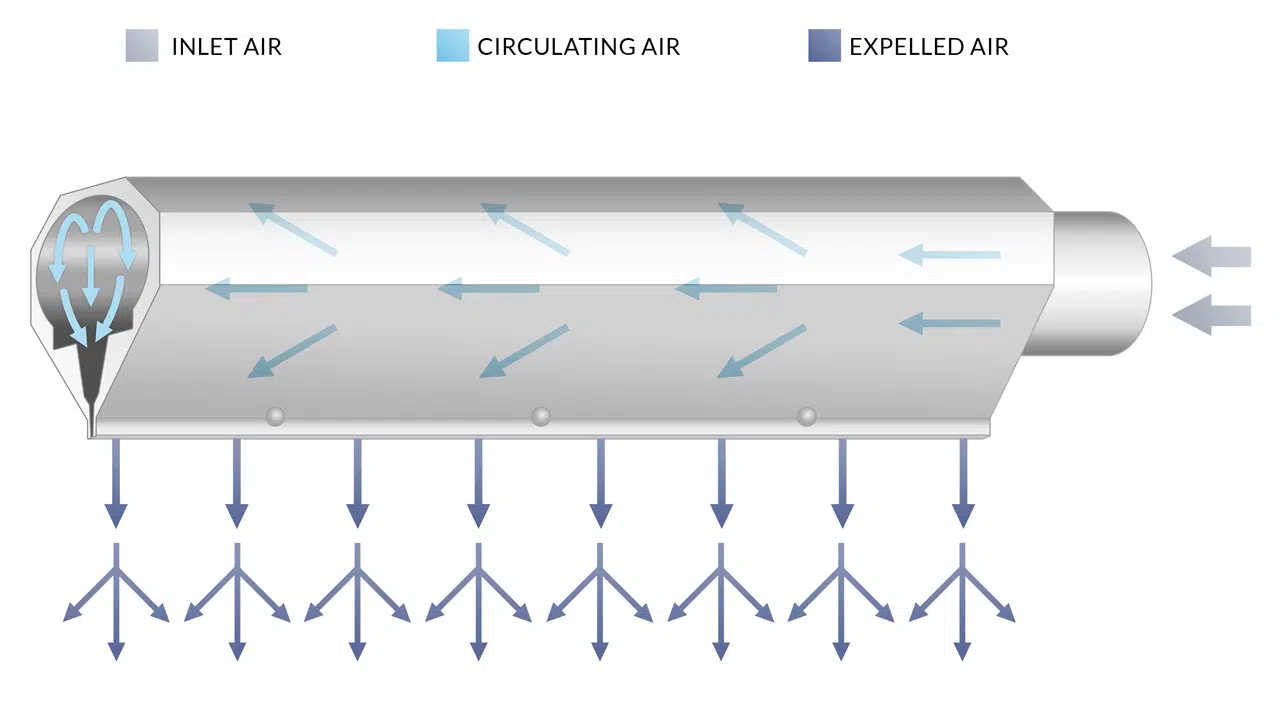

6 Air knives

The air compressor powers the air knife tool. The tool sprays compressed air on the material’s surface to remove or contain individual materials (solid or liquid).

During the production of printed circuit boards (PCBs), air knives remove solder paste and flux after conveyor belt cleaning. In addition, it is also used for drying after filling and cleaning bottles and cans, drying after automatic processing of metal castings, etc.

7 3D Printers

Air compressors have many applications, including 3D printing.

3D printers require a controlled atmosphere with inert nitrogen, for which they use nitrogen generators to convert clean, dry compressed air from oil-free screw air compressors into pure nitrogen.

8 Hi-Voltage Pneumatic Circuit Breakers

The operating mechanism generates and stores energy to operate the circuit breaker. Compressed air becomes the energy source for the pneumatic operating mechanism for closing and tripping the high voltage circuit breaker. These pneumatic circuit breakers are called “jet circuit breakers.”

Air compressors store compressed air in an air receiver (air tank). When needed, spray it into the arc chute. This pushes away the moving contacts. As a result, the connection is pulled apart, and the air shocks carry the ionized gas and support the arc extinguishing.

If you are related to any of the above industries, your product may require an air compressor. The question you may face when buying is the quality and price of the air compressor. To solve your problem, BENEAIR offers a wide variety of air compressors with the excellent build quality and reasonable prices.

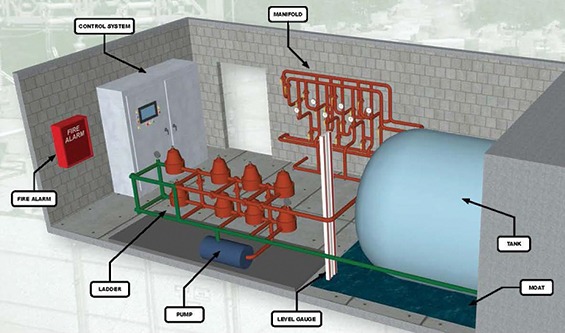

Common Equipment for the Electronic Applications

If compressed air is used in the precision electronics industry, we recommend a 100% oil-free air compressor with a desiccant air dryer and filter.

For low-risk compressed air for production lines, oil-lubricated air compressors with refrigerated air dryers and filters can be an option if the budget is limited. Still, in the long run, oil-free air compressors can not only produce high-quality oil-free air Air compressors. Air compressors Clean air, but with lower maintenance and energy costs.