Wastewater Treatment

Air Compressor for Wastewater Treatment

High-pressure air compressor for Aerospace

Not PISTON

No more high noise and vibration

SCREW TYPE

Patented two-stage single screw compression

Not BOOSTER

No more high maintenance costs

We have more than 30 years’ experience.

Applications for Water Treatment Air Compressor

Air compressors in wastewater management help treat wastewater for safe disposal or further use in domestic or industrial settings.

Wastewater treatment plants extract, separate, and treat as many suspended solids as possible from wastewater.

The following are examples of applications of air compressors in wastewater treatment processes.

Slurry Liquid Pumps

The slurry is a semi-liquid mixture of contaminants floating in the water, and wastewater from sewage treatment plants may contain biosolids, abrasive materials, and slurries.

Slurry pumps use air compressors to treat water and handle slurries from industrial or household waste.

Air compressors ensure slurry suspension while treating wastewater and separating the process mixture.

The air compressor provides sufficient pressure to transport the slurry between the tanks when treating wastewater.

Desalination

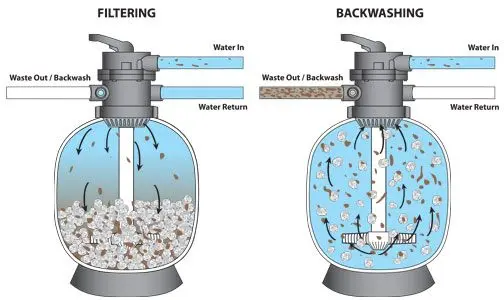

Backwashing is pumping water in reverse motion through a filter to remove the water’s impurities or unwanted substances, such as sand.

In wastewater treatment plants, air compression is intermittently used to backwash water and break down dense materials by expanding filter beds.

The air compressor pumps the purified backwash water and suspends the sand, which is then transported through the sand filter to the disposal site.

Backwashing Sand Filters

Backwashing is pumping water in reverse motion through a filter to remove the water’s impurities or unwanted substances, such as sand.

In wastewater treatment plants, air compression is intermittently used to backwash water and break down dense materials by expanding filter beds.

The air compressor pumps the purified backwash water and suspends the sand, which is then transported through the sand filter to the disposal site.

Purification

Wastewater is purified by air compressors to produce viable, clean water for safe runoff, discharge into rivers or oceans, or reuse for industrial and domestic use.

If wastewater is not purified, it will pollute and contaminate natural aquifers and domestic water, so purification is a crucial step.

Most wastewater treatment plants use activated sludge tanks and air compressors to maximize water purification.

The activated sludge tank first treats the water; then, the air compressor provides pressure to generate higher oxygen levels for water purification.

Removal and Disposal

Air compressors are used in wastewater removal and treatment where suction pressure is critical as they remove impurities and flush out unwanted debris.

Air compressors provide accurate suction pressure levels for sewer cleaning and can clean the entire sewer system network that conveys wastewater.

Air compression in wastewater treatment is used in the central vacuum system of the treatment plant to provide sufficient force to transport the wastewater to the treatment site.

Digestion Tanks

Digestors in wastewater treatment uses anaerobic digestion to break down solid organic waste in wastewater.

Air compression is used for the function, cleaning, and maintenance of digester tanks.

As the wastewater flows through the clarifier, the digester breaks down the wastewater and produces wastewater digester gas.

Air compressors play a vital role in digestion tanks because compressed air activates the tanks before oxygen is mixed with the decomposed sewage, producing and retaining gas.

Biogas is a source of methane used as an energy source in other manufacturing processes.

Why Should We Choose Screw Type Compressor

30~40bar

Air Compressor:

Screw VS Piston

| Comparison | Oil-free Screw Air Compressor | Oil-free Piston Air Compressor |

|---|---|---|

| Air quality | 100% Oil-free | Air cylinder Oil-free, Crankcase has oil |

| Compression Method | 2 Stage Screw | 3 Stage Piston |

| Lubricating Medium | Pure Water | None |

| Temperature | Low: < 55℃, No need for cooling | High: 125~200℃, After cooling about 60℃ |

| Cooling Method | Air Cooled or Water Cooled (Only one cooler for lubricating water) | Water Cooled (Two interstage coolers and one aftercooler for compressed air) |

| Rotate Speed | 3000 r/min Ideal Speed | 600~900 r/min Low Speed |

| Vibration and Noise | Balance and Simple structure, low vibration, and less noise | The pistons rise and fall or move back and forth, causing too much vibration and Noise |

| Costs – Purchasing | More | Less |

| Costs – Foundation | No costs | Require foundation and grouting due to high unbalanced forces & high vibration. |

| Costs – Maintenance | Only Air filter elements and Water filter elements | High wear & tear of moving parts like piston rings, valves, etc. |

| Costs – Energy (e.g. 40bar 10m3/min) | Motor Power: 112kW (1st stage 75kW+2nd stage 37kW) | Motor Power: 132kW |

| Capacity Loss | There is no loss / very minor loss in Capacity over a period. | There is De-ration in Capacity due to wear and tear in cylinder crankcase, piston rings, pistons, and valves. |

Common Equipment for the Water Treatment Applications

Oil-lubricated air compressors with refrigerated air dryers and filters can be an option if you’re on a budget. Still, in the long run, oil-free air compressors not only produce high-quality, oil-free, clean air but also provide Maintenance services energy costs are also lower.