What are the Environmental Impacts of Oil-Free Air Compressors?

Introduction

Oil-free air compressors are an increasingly popular choice for industries looking to reduce their environmental impact. While traditional oil-lubricated compressors have been the norm for many years, they come with a range of environmental concerns. These include oil leaks, the disposal of used oil, and the release of harmful emissions into the atmosphere; issues that are not present in oil-free compressors. In this article, we will explore the environmental impacts of oil-free compressors in more detail.

Reduced Carbon Footprint

One of the most significant benefits of oil-free air compressors is their reduced carbon footprint. Unlike traditional compressors, oil-free compressors do not emit harmful greenhouse gases that contribute to climate change. This is because they do not rely on fossil fuels, and as such, they do not produce harmful emissions when in use. This makes them an ideal choice for businesses looking to reduce their carbon footprint and operate more sustainably.

Reduced Power Consumption

Another significant environmental benefit of oil-free compressors is their reduced power consumption. Because they do not require oil to operate, they experience less friction and, in turn, require less energy to function. This means that businesses can save money on energy costs while also reducing their carbon footprint.

Reduced Waste and Pollution

Oil-free compressors also generate less waste and pollution than traditional compressors. This is because they do not require oil changes, which can create hazardous waste that must be disposed of correctly. Additionally, oil-free compressors do not produce oil leaks, reducing the risk of environmental pollution. This makes them an ideal choice for businesses that are looking to operate more responsibly and reduce their impact on the environment.

Conclusion

Oil-free air compressors have a range of environmental benefits that make them an ideal choice for businesses looking to reduce their impact on the environment. Reduced carbon footprint, reduced power consumption, and reduced waste and pollution are just some of the reasons why businesses are making the switch to oil-free compressors.

About Us

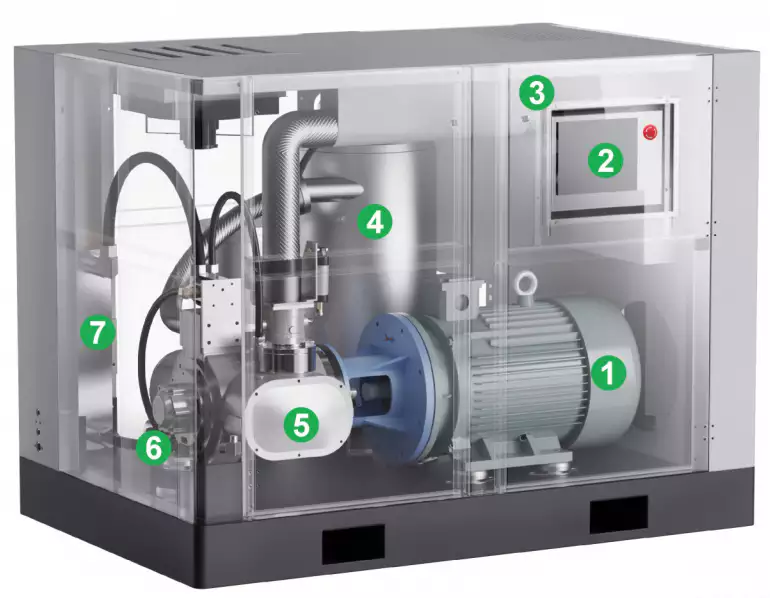

As a professional Oil free screw air compressor factory, we are committed to providing high-quality products to our customers. We offer a range of oil-free compressors, including 8-12 bar Water-Lubricated Air Compressors, 20-40 bar Oil-Free Screw Air Compressors, and Oil-Free Scroll Air Compressors. You can learn more about our products by watching the following video:

Oil-Free Air Compressor Purchasing Guide

If you’re considering purchasing an oil-free air compressor, there are several factors to consider. These include:

- PSI requirements

- Airflow requirements

- Portability

- Noise level

- Maintenance requirements

- Brand reputation

By considering these factors, you can ensure that you choose an oil-free air compressor that meets your specific needs and operates as efficiently as possible.

Author: Miya