A Comprehensive Introduction to Blowing Machines

The blowing machine, a crucial element in the realm of manufacturing, is a device that moulds plastic granules into hollow objects by blowing a gas-filled cavity within the molten plastic. The process of using a blowing machine is often referred to as blow moulding. This technology is widely used in the production of containers, bottles, or other hollow shapes of plastic materials.

Key Features of Blowing Machines

Blowing machines are versatile, fast, and efficient, making them a staple in various industries. They offer a wide range of benefits, such as high productivity, the ability to produce complex shapes, and the production of seamless parts. They also have the advantage of being able to create large hollow objects, which would be difficult to produce using other methods. Moreover, these machines are designed for easy operation and maintenance.

Maintenance of Blowing Machines

Regular preventive maintenance is a must for blowing machines to ensure their longevity and optimal functioning. This includes routine inspection of machine parts, timely replacement of worn-out components, and regular lubrication of moving parts to reduce friction and wear. The machine should also be kept clean to prevent dust or debris from affecting its operation.

Application Scenarios of Blowing Machines

Blowing machines are widely used in various industries, including packaging, automotive, and pharmaceutical. They are especially popular in the beverage industry for producing plastic bottles. Other applications include making containers for household and industrial use, toys, and even parts of medical devices.

EVER-POWER: Your Trusted Provider of Blowing Machines

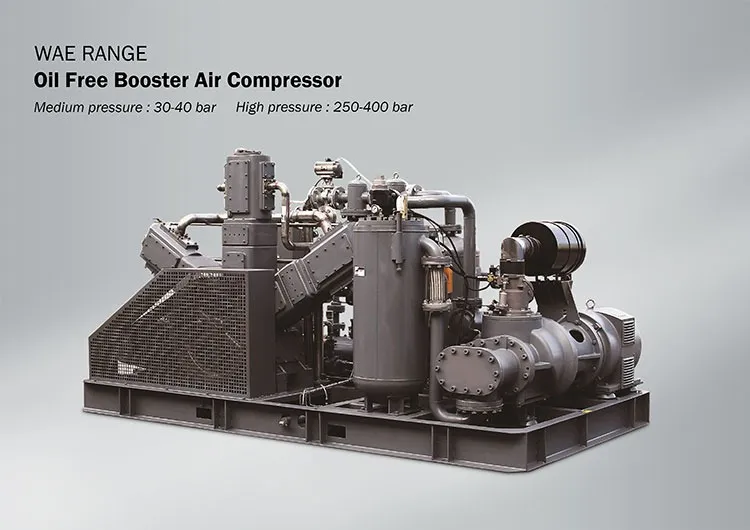

When it comes to reliable and efficient blowing machines, EVER-POWER stands out from the crowd. As a leading manufacturer specializing in the production of air compressors for blowing machines, EVER-POWER provides an extensive range of high-quality products, including oil-free screw air compressors, high-pressure micro-oil screw air compressors, micro-oil screw air compressors, scroll air compressors, piston oil-free air compressors, air compressors for laser cutting machines, and bottle blowing machine products.

With a strong commitment to quality and customer satisfaction, EVER-POWER ensures that every product manufactured in our factory meets the highest industry standards. We invite you to explore our products and see the difference that EVER-POWER can make in your manufacturing process. Make your purchase today and experience the efficiency and reliability of our air compressors for blowing machines.

FAQs About Blowing Machines

1. What are the main features of a blowing machine?

Blowing machines are known for their speed, versatility, and efficiency. They can produce complex shapes and large hollow objects with seamless parts.

2. How should I maintain my blowing machine?

Regular preventive maintenance, including routine inspection, timely replacement of worn-out parts, regular lubrication of moving parts, and keeping the machine clean, is essential.

3. Where are blowing machines commonly used?

They are widely used in various industries such as packaging, automotive, and pharmaceutical. They are particularly popular in the beverage industry for producing plastic bottles.

4. What products does EVER-POWER offer?

EVER-POWER offers a wide range of air compressors for blowing machines, including oil-free screw air compressors, high-pressure micro-oil screw air compressors, and others.

5. Why should I choose EVER-POWER?

EVER-POWER is a trusted manufacturer with a strong commitment to quality and customer satisfaction. Our products meet the highest industry standards, ensuring efficiency and reliability in your manufacturing process.